To take advantage of better technology and current tax credits, wind-energy facility owners are repowering their sites, often before the end of the turbines’ expected service lives. Through repowering, owners can boost power capabilities, sometimes by running fewer machines, as well as add to the grid without investing in an entirely new facility, experiencing significant permitting requirements, or needing new electrical interconnections.

What exactly does it mean to repower a wind farm?

There are two options when repowering a wind farm: full repowering or partial repowering. Full repowering involves completely dismantling and replacing turbine equipment at an existing project site. Partial repowering is defined as installing a new drivetrain and rotor on an existing tower and foundation. Partial repowering allows existing wind-power projects to be updated with equipment that increases energy production, reduces machine loads, increases grid service capabilities, and improves project reliability at a lower cost and with reduced permitting barriers relative to full repowering and greenfield projects.

Wind repowering — the combined activity of dismantling or refurbishing existing wind turbines and commissioning new ones — plays an important role in the industry. By modernizing the existing wind fleet, repowering sets the stage for future wind industry investments and helps maximize wind energy use in the coming energy transition.

When does it make sense for wind farm owners to consider repowering?

Wind repowering is fundamentally an investment opportunity for the facility owner, enabling owners to retrofit power plants on existing sites with new and/or refurbished technology, including building taller, more efficient wind turbines to increase productivity. By using existing grid connections and infrastructure, repowered projects can often gain further cost-saving advantages compared to new greenfield (or vacant lot) developments.

What are the challenges one might encounter when repowering a wind farm?

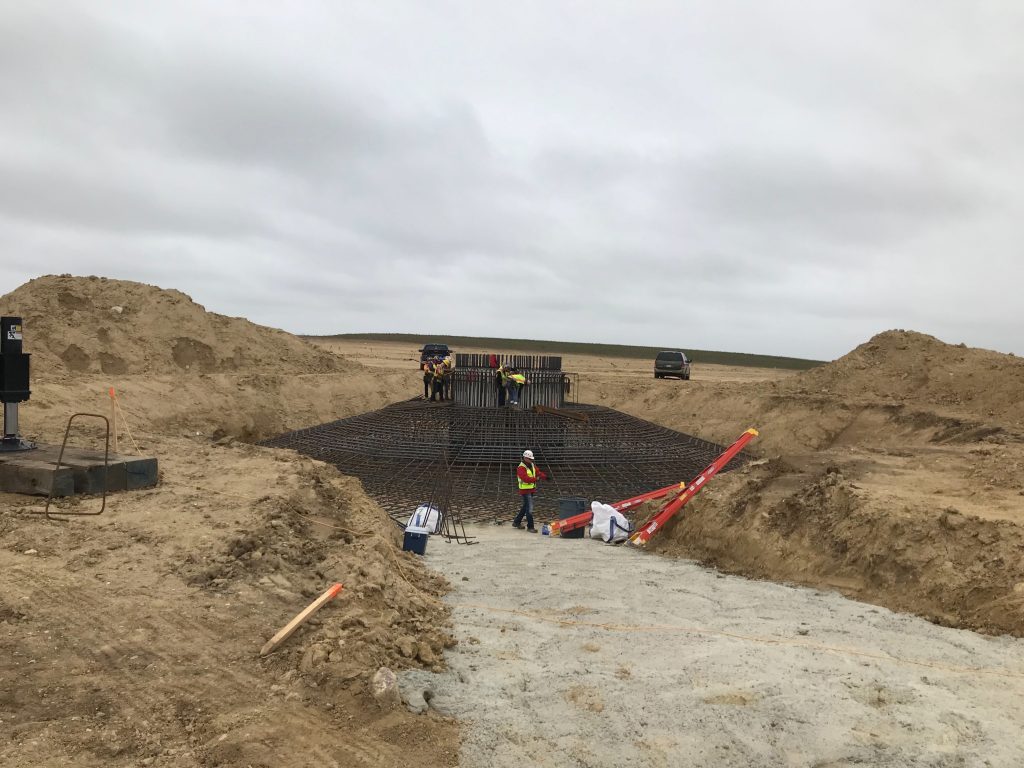

The costs associated with constructing or modifying existing foundations to support new turbines can be significant. Foundation work is sometimes required, but not always, and is dependent on engineering evaluations. Barr has developed an industry-leading program to evaluate existing wind-turbine foundations for repowering potential — an approach widely accepted by independent engineers, financial institutions, and presented in detail at industry events.

The first step in the process is a desktop evaluation to determine if the proposed foundations can support the new tower loads. These evaluations rely on design experience, current design practices/codes, and a database of historical foundation performance. Based on these evaluations, a determination can be made whether the new specifications can be met.

If the desktop assessment produces an acceptable outcome, the results are then validated with a field assessment. Field investigation is tailored to each project and based on the results of the desktop study, but it typically includes structural health monitoring (SHM) to determine a sample size of foundation performance while turbines are operating. The assessment can also include visual inspections and coring inside the foundations to check for cracking or hidden issues.At times, the desktop studies and investigations can result in uncertainty. Barr specializes in evaluating this risk and helping clients make decisions on how best to proceed. Whether the conclusion is to reuse the existing foundations, as is, and implement a risk-reduction monitoring program, or to design upgrades or modifications to the existing structures, Barr partners with owners to complete the necessary evaluations and design documents.

Is there any current funding available for wind-repowering projects?

Over the past several years, companies repowering wind facilities used the Renewable Electricity Production Tax Credit (PTC), which was phased out at the end of 2021. With the passage of the Inflation Reduction Act (IRA), the PTC has been extended through 2024 for wind-energy projects that begin construction prior to January 1, 2025. In 2025, the PTC will be replaced by the new Clean Electricity Production Tax Credit (45Y), which will support any net-zero power generation technology, including wind facilities, for the following 10 years.

According to previous Internal Revenue Service (IRS) guidance, each wind turbine, pad, and tower is treated like a separate power plant or “facility.” The IRS uses the 80-20 test to determine whether the facility is “new” and thus qualifies for the tax credit. The amount spent on repowering the facility must be at least four times the value of the used parts retained from the old turbine, pad, and tower. Repowering facilities can also qualify for additional incentive boosts from the Clean Electricity PTC if they meet the new prevailing wage and apprenticeship requirements. Additional incentives may be available if the facility is in an energy community or meets domestic content requirements, as defined by the IRS.

How can Barr help?

Since 1998, Barr has worked on more than 400 wind-power projects in 30 states, Canada, Mexico, and South America. In the United States alone, Barr has provided engineering services for more than 50 percent of the megawatts installed. Barr assists wind-power clients with pre-construction permitting and geotechnical investigations, foundation design, construction oversight, repowering evaluations, crane-walk assessments, and damage evaluations to O&M services.

For clients, the existing condition of wind-turbine foundations and associated investigation results can be a gray area; Barr specializes in evaluating risk and helping clients make decisions about moving forward.

Originally published in Barr Engineering Co.’s Insights blog.