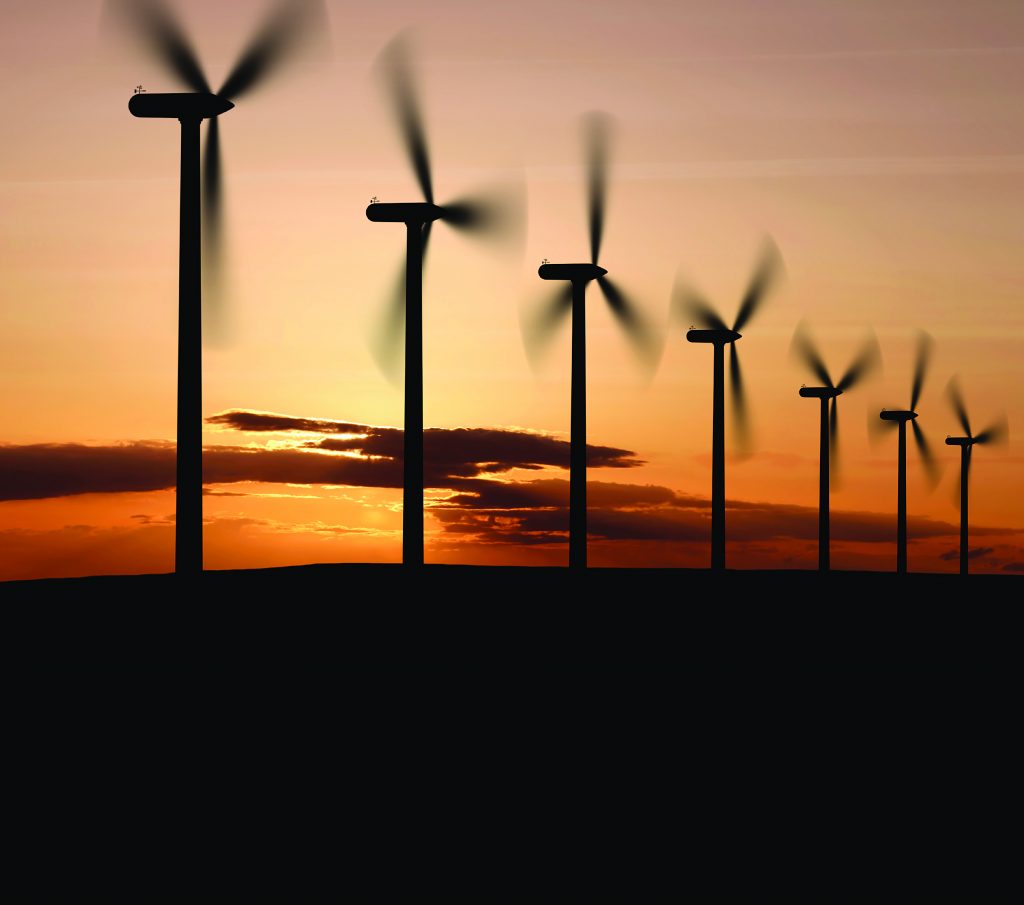

Humans have been making things from copper for more than 8,000 years. Through the centuries, this versatile, highly conductive metal has gone from being a key ingredient that helped birth the Bronze Age to the Modern Age, where it has become an essential element in the functioning of green-energy systems, including wind plants.

“Wind power is becoming a major player in North America as society transitions to cleaner, more sustainable practices,” said Zolaikha Strong, director of energy policy and electrical markets for the Copper Development Association.

As new onshore and offshore wind installations continue to be built from coast to coast, reliable, conductive, and flexible materials are needed to support the complex electrical infrastructure within these systems.

“You can’t just add more fuel to a wind turbine,” Strong said. “Wind plants rely on weather, so its infrastructure must be able to withstand harsh conditions to effectively support transitions of power generation. Copper is the most conductive metal to meet these demands, and its efficiency ensures that reliability is met in supporting onshore and offshore wind installations.”

Offshore Positives

With the growth of offshore wind installations, copper is an even more significant material component, according to Strong.

“You can’t put a turbine in the middle of New York City,” she said. “But you could build off the coast and export that electricity using underground transmission lines into Manhattan, the other boroughs, or a populous state such as New Jersey.”

This approach demands advanced wiring installations that can handle large energy flows and power transitions since it’s very difficult to fix issues buried in the ocean, according to Strong.

“In comparison to onshore wind plants, offshore farms depend on underground transmission to interconnect the wind facilities to land,” she said. “Copper is a necessity for the cabling/wiring itself, but it’s also critical for handling the system’s resilience.”

Copper vs. Aluminum

As the construction of wind farms continues, other materials, such as aluminum, have been discussed as copper substitutes; Strong believes copper is still the superior choice.

“Aluminum doesn’t meet copper’s conductivity or its resistance to thermal expansion,” Strong said. “If you want your system to work without worrying about reliability or interruptions then it’s simple: Just use copper.”

“When you look at the life-cycle assessment, generally you see an increased amount of aluminum is needed to reach the performance level that would be required from a smaller quantity of copper,” she said. “Because of this reason, among others, copper is still preferred when it comes to offshore wind and underground transmission.”

Copper’s Future

A recent study by Navigant indicated copper use in the wind industry will peak by 2020, but Strong said there are several variables that might come into play that would affect that prediction.

”However, strides in public policy decisions and regulations will create advances in renewable portfolio standards, which may require more renewable resources,” she said.

Strong pointed to many East Coast states, such as Massachusetts, New Jersey, and Virginia, that are developing robust offshore wind plans. These initiatives will play a role in some of the projections on how many wind turbines — and therefore, how much copper — are going to be needed.

Copper Supply

With so many wind projects in the pipeline, and copper being an essential material, there is a question of the availability of copper to meet these demands. Strong said that between copper in production and copper in the scrap stream, the U.S. can meet that demand.

“The metal is infinitely recyclable,” she said. “You can reuse copper scrap that’s a hundred years old with no loss of performance. And thanks to electrical wiring in particular, the scrap stream available to us is robust.”

And with the renewable industry’s need for more copper, Strong said the Copper Development Association has a positive outlook on what the future may bring.

“The copper industry is really looking forward to seeing increased regulations and policies that help develop more offshore wind in North America,” she said. “Electricity produced offshore is dynamic and can help meet energy demands across the country.”