Researchers at the U.S. Department of Energy’s (DOE’s) National Renewable Energy Laboratory (NREL) have determined how to transport massive wind-turbine blades to parts of the country at a lower cost than segmented blades, but the solution will require some flexibility on the part of industry.

Manufacturing blades that can bend with “controlled flexing” will allow railroads to ship longer blades around the United States. Because of bends, twists, and turns in railroad lines, the upper limit for transporting single-piece land-based blades by rail is currently 75 meters.

The conceptual design envisioned by researchers would stretch that limit to 100 meters or beyond for land-based turbines. Blades of this length are already being proposed for offshore wind turbines and can be transported via barge, but they have not been installed inland due to the transportation constraints.

For land-based turbines, the longer blades could be shipped attached across the length of four railcars.

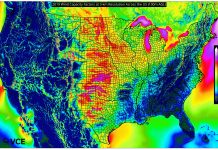

Longer blades and taller wind turbines allow for the greater production of energy, even in areas where wind speeds are low. Seeking an economical solution to installing wind turbines has kept wind farms from regions where the resource could potentially be harvested, including the southeast United States.

The flexible blade technology may enable more deployment in these areas in the future due to the lower cost. Lowering the cost of transportation and enabling rotors with a higher capacity factor could make these deployments more economically feasible.

“This research can aid in massive deployment of wind energy in different regions of the country—even parts of the country that typically haven’t seen as much deployment,” said Nick Johnson, a mechanical engineer at NREL’s National Wind Technology Center and co-lead of the U.S. Department of Energy’s Big Adaptive Rotor Project (BAR).

Blades already possess some flexibility. Traditional blades can have deflections of about 10% of the blade length from the root where they are attached to the turbine to the tip. For the blades envisioned by the BAR research, this increases to 20% to allow for the flexibility required for rail transportation.

Johnson said he sees industry adopting the flexible blades about five years out. “We have an industry advisory panel and have had great input and feedback from the members. They’ve kind of steered us in this direction. They think it’s a promising idea, and certainly worthwhile as the impact could be significant,” Johnson said.

More info www.nrel.gov