2020 proved to be a pivotal year for the global wind industry, as it recorded its best 12 months with the installation of more than 93 GW of wind power. In Europe specifically, 14.7 GW of new wind capacity was reported; 80 percent of which was installed onshore.

Wind turbines typically require preventative maintenance checks two or three times a year to ensure optimum operational efficiency, performance, and to streamline costs. A good quality, modern turbine that has been routinely maintained has an expected lifecycle of 20 to 25 years.

However, as the turbine ages, maintenance costs increase, and power capacity diminishes, during which time smaller, more effective turbines are introduced into the market, making it necessary for wind-farm owners to upgrade or repower facilities to meet the increasing demand for renewable energy.

Ensuring that the access platforms and cranes used to perform this maintenance work are as stable as possible is vital if they are to be used safely and effectively. So, it is extremely important that ground conditions are accurately assessed, especially given that no two wind-farm sites have the same conditions underfoot.

A Firm Foundation

There are many methods available to improve the condition of the ground and increase or maintain its load bearing capacity. However, these methods are subject to deterioration of the ground surface — and what lies underneath can further complicate what is already a complex process to execute a project in a safe, efficient, and cost-effective manner.

Typically, wind farms are installed in remote or isolated environments, along coastal paths, farmland, or on river deltas where the soil is weak and prone to settlement issues, creep, or wash-outs. After initial construction at these sites, the crane pads are removed, but the hardstand frequently remains for the purpose of carrying out maintenance.

However, ground conditions can change over time and are not typically monitored in the same way as other maintenance factors, such as the condition and performance of the turbines. This means the extent of any deterioration is often unknown, making the specification of maintenance works unclear.

What Lies Beneath

Understanding the composition of the subsoil and identifying potential weak spots is vital to ensure the safe and efficient completion of lifting and exchange works. Normally a ground survey is done and a geotechnical report on the wider area is provided.

However, this does not take account of the variances in ground conditions between different parts of a site, and the load bearing capability at specific points — for example where the laydown or storage areas are needed — is often not fully known.

This is where Mammoet’s expertise comes into its own, focusing specifically on the point at which the main crane hardstand, laydown or storage areas will be, as these will be the points that will experience the highest forces. Using proprietary tools, Mammoet can calculate the pressure exerted at the point the ground will be loaded most heavily — when the crane’s boom goes up — and allow for planning based upon the highest level of loading.

Typically, plate testing is undertaken to assess the strength of the ground below heavy lifting operations. However, this is often insufficient, as this does not consider the depth of influence that loading has into lower subsoils.

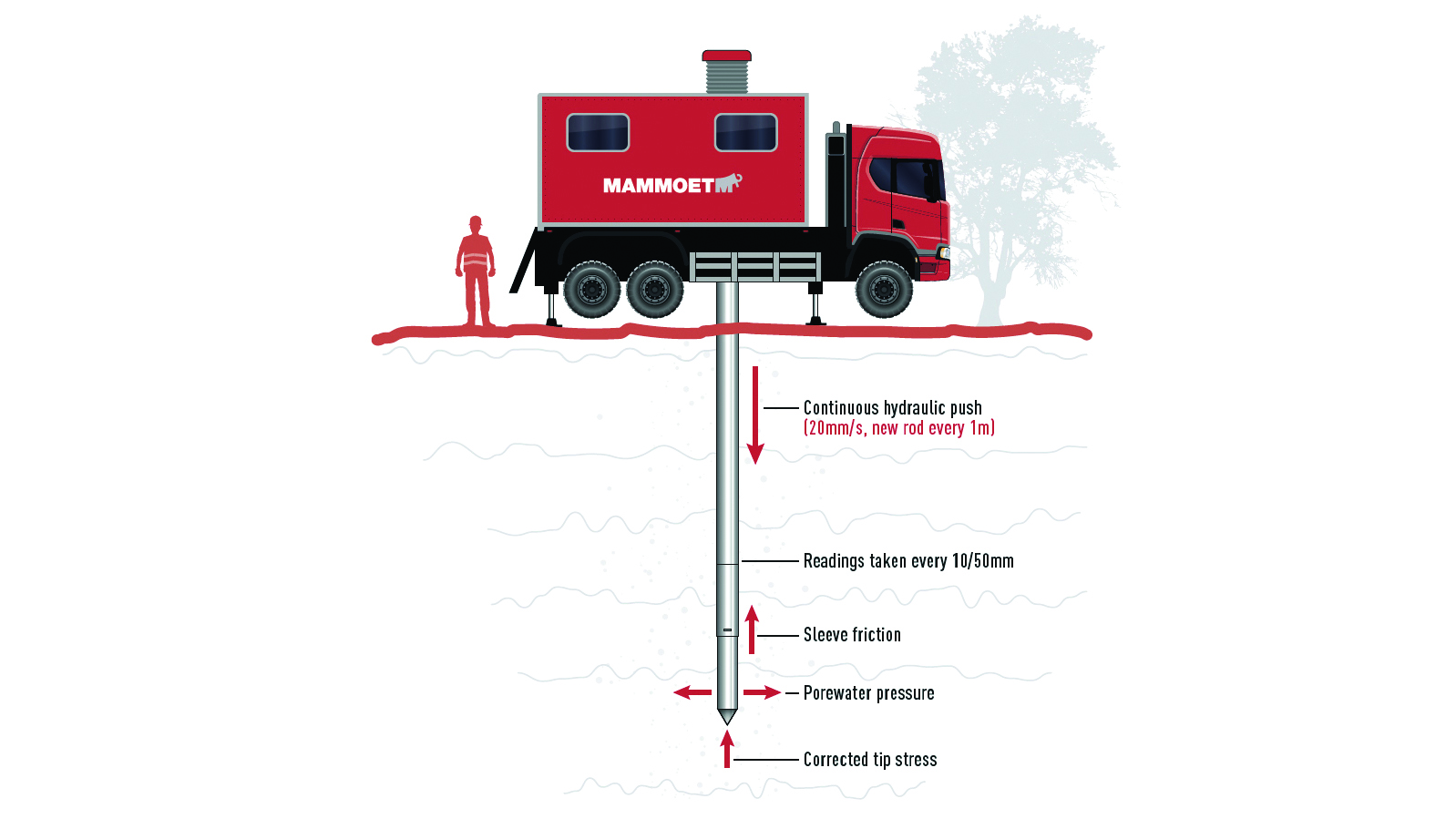

Instead, one or more cone penetration tests (CPTs) can provide clarity on what the layers beneath the surface consist of. This identifies any risk factors affecting the subsoil and can be further illuminated by 3D simulation of the installation or other load cases to share information on risks with all stakeholders.

Scarcity of Aggregates and Space

Aggregate materials are traditionally used to construct the hardstand and to reinforce the quality of the soil. However, we are faced with a global shortage of such materials in the near future. Aside from the obvious impact on the construction sector, the scarcity of granular materials has huge ramifications for onshore wind power.

Lack of storage space around the installation is another challenge. Because wind farms are typically constructed in remote locations, it isn’t possible to permanently store the large and heavy equipment needed for their maintenance. Instead, this machinery must be transported to site, often over multiple surface types. Luckily, solutions exist to quickly bring on-site surfaces up to the high standard required for heavy lifting projects.

Mammoet’s Enviro-Mat offers wind-farm operators an efficient, cost-effective, and sustainable solution that increases the ground bearing capacity of a large area within a short timeframe and, therefore, is an ideal solution for the wind sector. Enviro-Mat is a highly developed soil improvement methodology, consisting of a combination of local soil, cement, and additives including all-natural minerals, which increases ground bearing capacity up to customer specifications.

It is a proven solution for improving the condition of hardstands and pads on site at wind farms and allows operators to carry out work much more quickly using locally available cranes. It can also be used to upgrade the bearing capacity of existing roads to withstand heavy transport and for storage of tower sections, nacelles, blades and — in the offshore wind sector — monopiles and transition pieces.

It uses locally available soil and granular materials and doesn’t require additional aggregate or materials to be sourced and transported to site. It is also much faster to install than other ground reinforcement methods and needs less time for preparatory groundworks.

All these factors combined means using Enviro-Mat also reduces the overall carbon footprint of a project. It also allows the site to be given back to nature once work is complete, as it can be crushed back into the soil with no environmental impact.

Stronger Still

More recently Mammoet, together with the Dutch contractor Sterk B.V., has been testing its newest innovation: the Enviro-Wall-Mat combination.

The objective of the Enviro-Wall-Mat combination is to create a solid foundation in ground that has weak subsoil, without the need to pre-load the area beforehand. It works by creating a trench that is filled with locally sourced soil, cement, and additives to create a pillar-like “wall” under the Enviro-Mat surface, which prevents extreme settlements from occurring.

It almost goes without saying that time saved by not having to pre-load and compact the ground is time that can be spent assembling or maintaining a wind farm to increase its uptime. Working with customers during the feed stage of a project allows us to deliver engineering that adds real value to each project. By mapping material flows, we can deliver load bearing capacity exactly where it is needed, shaving weeks off wind-power projects.