When a company’s drive for innovation leads it to make the world a healthier, safer, smarter, and more sustainable place, it stands to reason what that company produces should follow through on that monumental task.

By focusing on software and technologies for the power and water industries, Emerson is striving to do just that.

“Our driving force has always been control systems and software for power generation,” said Jason Blackburn, Director of Global Product Marketing for Emerson. “We’ve traditionally been focused on conventional power, and now that focus includes supporting customers’ net-zero targets. Emerson’s solutions help customers confront the transitional challenges associated with meeting their sustainability goals by balancing the addition of more renewable energy — wind, solar, and battery storage — in their portfolios.”

Moving into Wind

Blackburn explained that Emerson’s stellar reputation in the power industry, combined with an extensive global service network, enables the company to be well-positioned to help customers optimize the management of renewable resources, especially wind-turbine generation.

“Over the past few years, we’ve been looking to extend our wind capabilities and exploring questions such as: Are there companies that fit with our automation profile? Are there companies that don’t necessarily make the equipment, but are leaders in building or providing automation platforms for wind OEMs and wind operators?” he said. “We examined the market, and we found our answer in Mita-Teknik, a leader in control automation for renewable power generation with a broad, comprehensive portfolio of solutions and services for wind.”

“Mita-Teknik makes turbine and pitch control systems for wind-turbine OEMs with a full suite of condition monitoring, SCADA, and asset performance management software that monitors wind parks to help determine asset health and optimize performance regardless of turbine type,” Blackburn said.

The acquisition of Mita-Teknik was complementary to Emerson’s existing automation portfolio and supports the company’s ability to help customers digitally transform operations and meet sustainability goals. It also aligned with Emerson’s long history of similar strategies that enable the company to offer a superior product for customers who want the option of maintaining and operating their assets independently without relying on OEMs.

“We liked Mita-Teknik because not only is the organization a major provider to OEMs, but it also has an extensive collection of solutions that can be used for retrofitting and modernizing wind controls,” Blackburn said. “This capability is of great interest to our utility customers who want to self-operate and self-maintain their assets.”

Combining Company Strengths

Another reason for Emerson’s acquisition was Mita-Teknik’s long, successful history in the wind industry and its work with other early Danish wind innovators to build wind-specific control systems.

“Mita-Teknik, founded in 1969, was one of the first companies to develop a wind-turbine controller,” Blackburn said. “The organization is headquartered in Denmark, a country that is known as a pioneer in the wind industry.”

By combining Mita-Teknik’s wind expertise and a strong presence in Europe and Asia, with Emerson’s world-class power generation leadership, especially in North America, Emerson significantly expanded its global reach in renewable energy, particularly in the wind sector.

“We have a lot of synergies with regard to longstanding customer relationships with utilities and the owners and operators of wind farms in North America,” Blackburn said. “Mita-Teknik has the best technology portfolio for wind generation. Integrating automation systems and software, industry leadership, and expertise into tailored, comprehensive solutions will help our customers in North America operate their fleets better.”

Unlocking Asset Data

Many of Emerson’s customers operate fleets of multi-OEM wind turbines, each using different automation systems, particularly on the SCADA or asset-management level, according to Blackburn. The OEM systems typically don’t provide access to all the data that customers need to operate their wind fleets efficiently and cost-effectively. Emerson’s solutions help customers tackle that challenge by offering software that works with 750 different turbine types, providing owners or operators a clear view of operations from an individual turbine to a full wind farm or a fleet of farms.

“Emerson’s wind solutions resolve two major customer pain points at the same time,” he said. “We offer a single pane of glass to view assets across the entire fleet that provides more insight than customers can normally get from their OEM solution.”

As assets age, customers will experience new challenges on the control side of the turbine.

“Owners and operators want to extend the lifecycle of their wind assets and control components, but they are faced with several issues,” Blackburn said. “One is difficulty obtaining obsolete spare parts. Another is, oftentimes, the customer’s OEM-provided control system is a black box. In other words, they cannot make modifications because the system is locked down.”

That’s where Emerson sees opportunities to provide full operational visibility that helps customers safely run a turbine differently to help improve its performance. Emerson does this by installing enhanced control strategies and software that optimize wind-turbine and wind-farm output to provide the lowest cost of energy.

Replacing the Control System

Emerson’s retrofit solutions replace legacy control systems with an open platform that enables customers to implement control strategies that optimize turbine output and extend lifespan.

“Our advanced control algorithms can increase AEP (annual energy production),” Blackburn said. “This includes optimization software that mitigates misalignment by autotuning the yaw position, resulting in a 2- or 3-percent increase of normal outputs over time as well as a long list of other improvements.”

According to Thomas Andersen, vice president of Renewable Energy Technologies for Emerson, customers have become savvier and more informed over the years about what to expect from their existing systems.

“In the last five to seven years, we have seen more interest from wind owners and operators to better understand their assets,” he said. “They want access to all the turbine data so they can analyze and optimize their production and lifecycle management.”

The Need for More Data

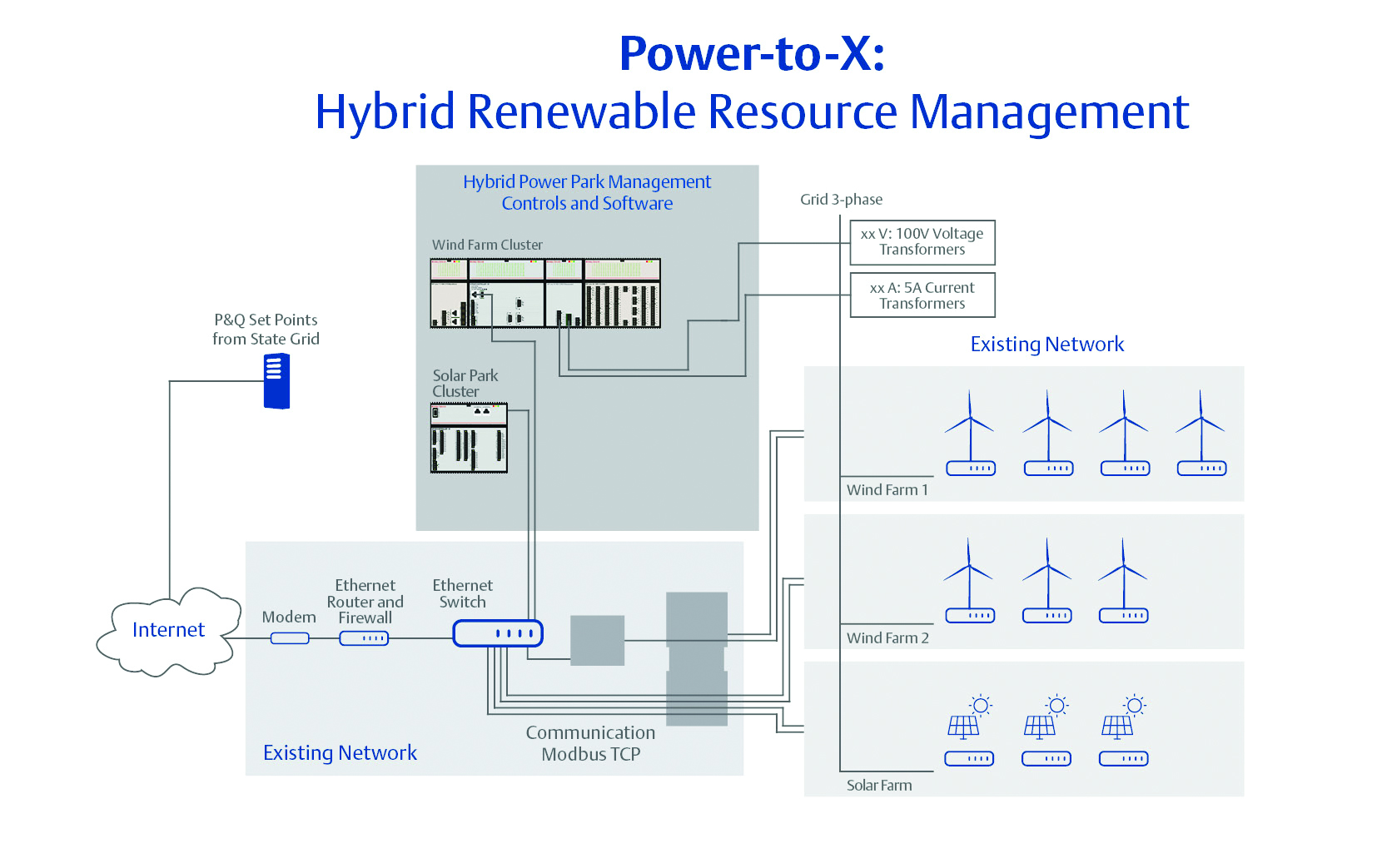

Data access and management become even more important as many renewables are hybridizing with a mix of wind turbines, PV solar, and battery storage to optimize energy output, according to Andersen. For successful hybrid operations, the operators must know, in detail, what is going on with each asset in real-time.

“Customers cannot get data from the OEM’s black box, and that’s what has been driving the retrofit market,” he said. “Our retrofit strategies provide full access to operational data. When combined with our vendor-independent SCADA system, the result is a comprehensive solution that delivers value across an organization, from a high-level KPI report for management to an engineering analysis tool that optimizes turbine operations.”

As an example of the services Emerson can perform, Blackburn noted a customer in Alaska with a set of older, remote turbines that needed to reduce turbine trips and improve performance; however, the OEM system did not allow access to the controls to reset the turbine after a trip.

“Before the acquisition, we worked with Mita-Teknik to replace the customer’s OEM-turbine controls,” he said. “As a result, they’ve experienced an increase in availability, and they are no longer dependent on the OEM, enabling them to operate their wind fleet as they want to operate it. We also implemented advanced control features that were not included with the original OEM system.”

“One-Stop Shop”

To that end, Andersen pointed out that Emerson is one of the few companies that has components to supply all the electrical equipment used in an asset, including pitch systems, control systems, and condition-monitoring systems.

“Outside of the turbine structure, we provide a SCADA system and asset management software. This makes us a one-stop shop for our customers,” he said. “They don’t have to pick and choose from different manufacturers and then struggle to get the disparate systems to function properly together. We deliver an integrated, tested system that is tailored to meet the unique characteristics of each turbine or farm. Our ability to simulate and calculate loads like those used when designing a brand-new turbine reduces risk.”

130-year History

Although Emerson’s history with wind is fairly recent, its track record with other platforms that built up its power industry expertise has existed since 1890. Emerson as a company has two main platforms: Automation Solutions and Commercial and Residential Solutions. Emerson’s renewable energy technologies and expertise, including wind, are part of the Automation Solutions platform that focuses on process, hybrid, and discrete industries.

With a long history of delivering power-industry-specific software and technologies, Emerson has been able to grow its install base to where it is today — automating more than 1.4 million MW of total global power. This is further enhanced by the Mita-Teknik acquisition, according to Blackburn.

Emerson’s solutions also automate about 12 billion gallons of water and wastewater treatment daily, an important function since a growing trend for the water industry is to operate around the clock with more reliable, resilient power. Water and wastewater plants are beginning to explore the use of onsite microgrids, which can include wind generation. Emerson’s microgrid integrated automation solutions platform controls and monitors all power-generating assets as well as water and wastewater treatment processes, providing customers with numerous operational and maintenance benefits.

Renewables Future

With its recent expansion into the wind industry, Emerson expects to continue to play an important role in the renewable sector by supporting its customers with their decarbonization efforts. Wind power is a key component of that, according to Andersen.

“We are an automation leader for manufacturers, OEMs, and owners of wind turbines with our ability to deliver a wide array of solutions and services,” he said. “We will continue to be a trusted adviser for many years to come. There’s no doubt that going forward we will see more hybrid power generating and energy storage plants that will require innovative technology to optimize operations. Our strategy is to be ahead of the changes happening in our industry and to be the go-to automation partner for delivering power-to-X, single resource, and hybrid solutions that provide more value to our global customers.”

An important aspect of that is the ability of those with wind-power generators to have greater control and insight into the operation of their turbines, according to Blackburn.

“In my opinion, customers who have owned and operated farms over the years, are in the best position to know the unique environments they operate in and the performance of their assets,” he said. “There’s a tremendous opportunity for customers who want to self-operate their facilities without reliance on the OEM. Our goal is to be the leading software and controls provider for the customers who want to do that and accelerate their journey to smarter, more sustainable operations.”

More info www.emerson.com/en-ca