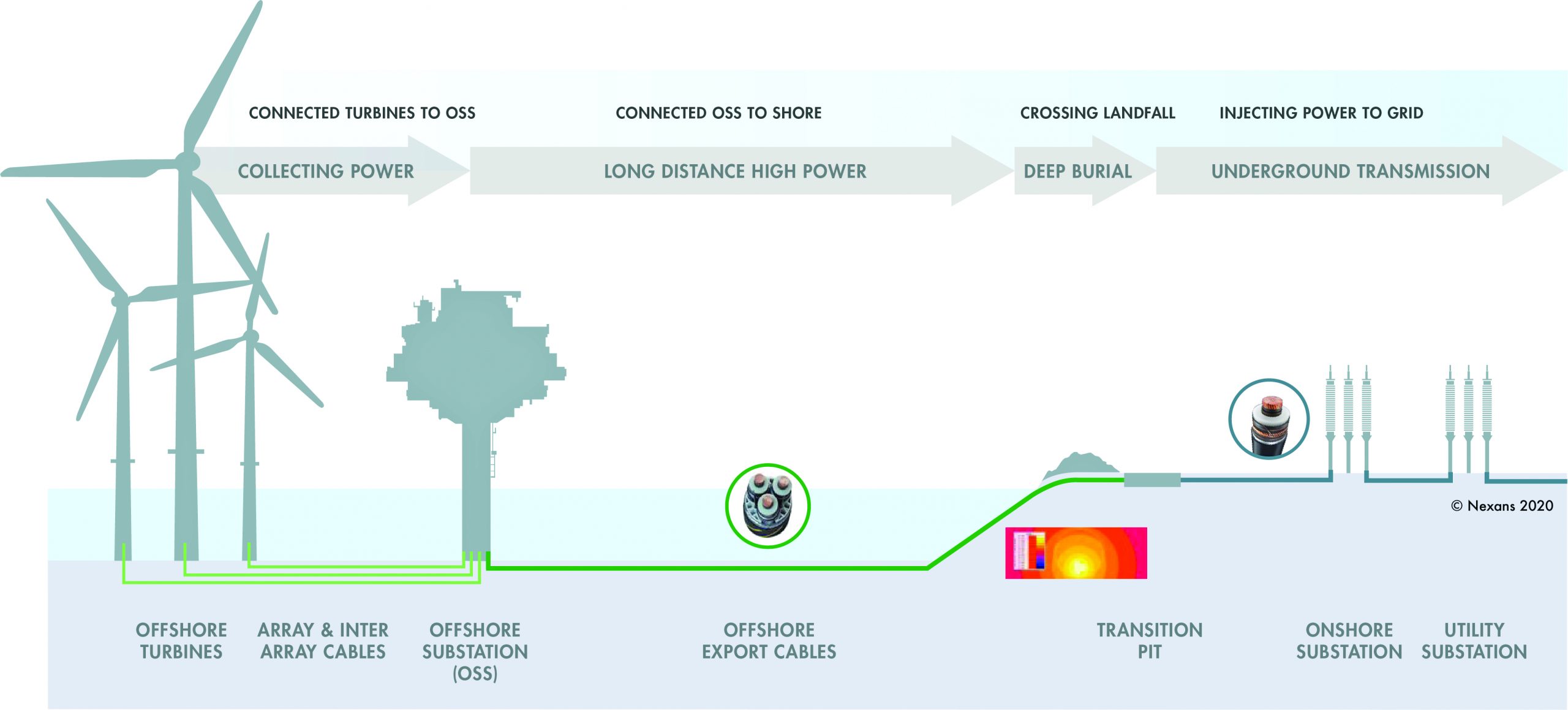

Offshore wind turbines are always an impressive sight as the massive structures rise out of the ocean and up into the atmosphere, transforming gusts of wind into electricity.

But, as that power is generated, it has to rely on miles and miles of cable to transport that energy to the thousands of homes and businesses that depend on it.

The responsibility for manufacturing and installing that massive amount of cable falls on Nexans, a company that has been dedicated to designing cables and cable systems for more than a century.

“One of our main business areas is export cables for offshore wind,” said Ragnhild Katteland, executive vice president for the Subsea and Land Systems Business Group at Nexans. “We delivered the 150kV subsea export cable to the very first commercial offshore wind farm, the Hornsea I in Denmark, at the beginning of 2000. The windfarm — and the cable — are still in operation. We have an end-to-end approach for this business; from front-end-engineering through design, manufacturing, and installation to inspection, maintenance, and repair.”

Working closely with clients

Nexans maintains a long-term partnership with its clients and works closely with them in order to contribute to the development of the industry by offering innovative solutions adapted to their changing needs, according to Katteland.

“The offshore wind farms are getting larger and farther away from shore,” she said. “This requires new solutions as well as dedicated, experienced, and professional teams to execute the projects.”

Those developments and innovations are an important ingredient for Nexans as the company strives for a carbon-neutral future, according to Katteland.

“Our purpose is to ‘Electrify the Future,’” she said. “Nexans has its own goal to be carbon neutral by 2030, and electrification is key to reach the ambitious carbon neutral goals set by the different governments and associations. We are delivering the export cable solutions for offshore wind farms as well as the interconnectors to make this happen. Offshore wind farms are safe and sustainable; it’s renewable, and it is really a way to have de-carbonized energy accessible to everyone.”

Start-to-finish involvement

In order to meet those admirable goals, Nexans is intricately involved in the development from the beginning, bringing together its clients and its suppliers to make up a robust supply chain, according to Katteland.

“Nexans can bring solutions and new developments to the offshore wind farms for them to move forward,” she said. “We’re not only bringing the product, we are installing and protecting a true end-to-end approach of the projects. We have formed a partnership with Bureau Veritas for certifying the way we are working on project management and risk management to ensure the best way of working and safest results for our clients.”

Meeting specific challenges

Every offshore wind farm has its specific challenges, and the experts at Nexans strive to meet and answer every customer’s needs, according to Katteland.

“To give the best support to our clients we need to understand the projects and stake holders,” she said. “And how to bring additional value on top of delivering the product and the installation itself.”

Nexans’ commitment to a project starts with early involvement and carries through to the very end, according to Katteland. But it doesn’t end there. Nexans is also involved in maintenance and aftermarket to ensure a reliable cable link.

Developing the U.S. market

With all its experience in the European offshore wind market, Nexans already has begun making inroads in the fledgling U.S. offshore wind market, according to Katteland.

“We have a long-term frame contract with Ørsted for using our cable manufacturing plant in Charleston (South Carolina) that we’ve now turned into a high voltage subsea plant,” she said. “That will be the first HV subsea plant in the U.S. From this plant, we will deliver the export cables for the wind farms to be developed by Ørsted and other potential U.S. offshore wind farm projects that we are following closely.”

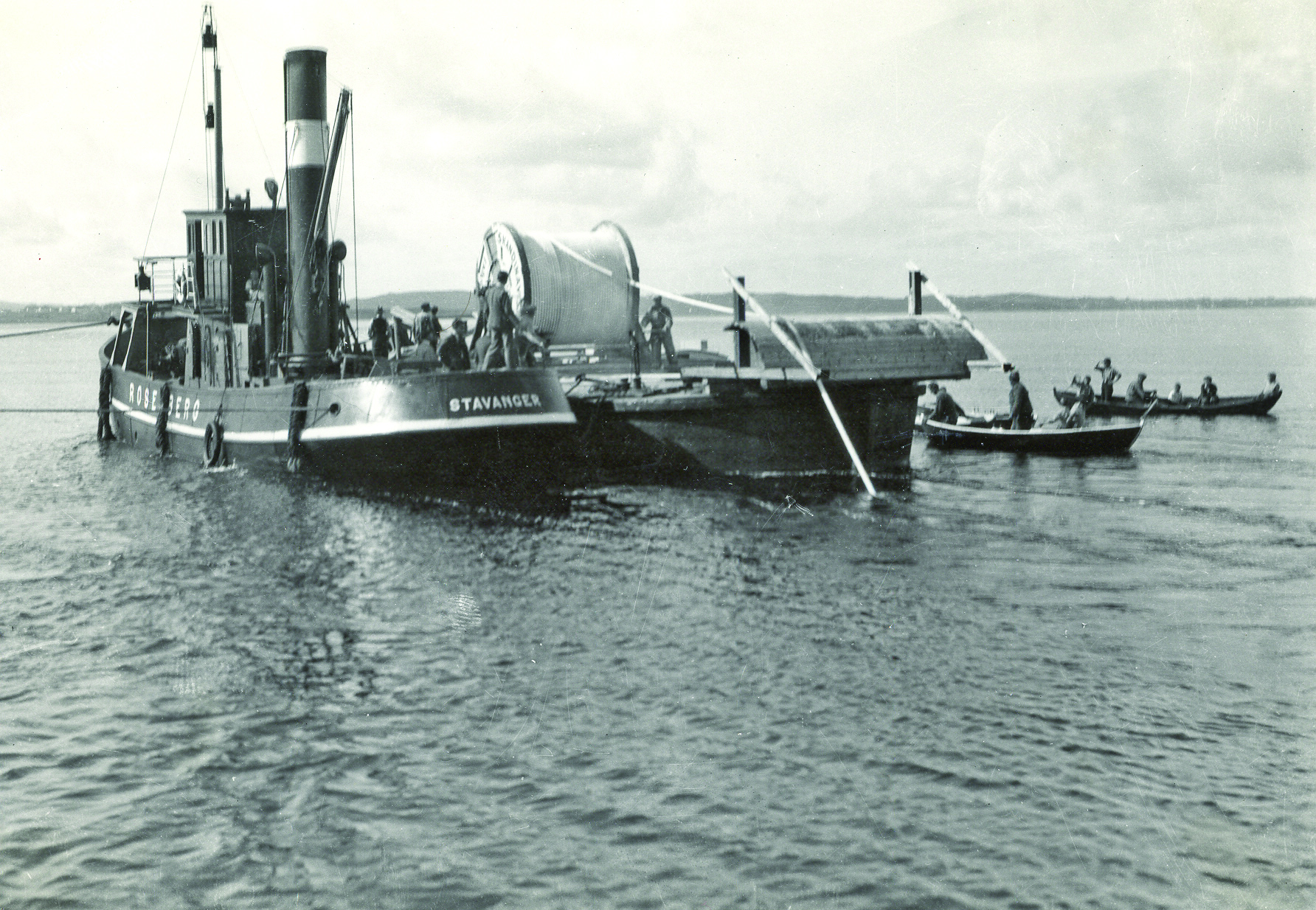

The road that has led Nexans to being a leading supplier of cables and systems to the wind industry is a long one.

120-plus year history

The company was founded in 1897 delivering cables and cable systems to a myriad of industries. In 2001, the cable and components part of the company was spun off from Alcatel to become Nexans.

At the beginning of the 1970s, Nexans’ HV subsea flagship plant, Halden, Norway, was constructed, as well as the C/S Nexans Skagerrak, Nexans’ laying vessel. Both were built for one project only — the first interconnector between Norway and Denmark, according to Katteland.

“That was our first-ever interconnection project,” she said. “And now we have a long history of solid experience of cable manufacturing and cable installation, both subsea and onshore.”

Next up: Floating farms

Nexans continues to grow within electrification as Katteland emphasized that the next phase after the bottom fixed offshore wind farms will be floating offshore wind farms.

“For the floating offshore wind farm, dynamic cables are needed, as opposed to static cables, which are used for bottom fixed offshore wind farms,” she said. “We have gained valuable experience and technology knowledge from previous engagements in the oil and gas industry, which we now are using for the offshore wind industry.”

By using the knowledge Nexans learned from existing industries, the company was able to deliver cables to an offshore floating wind farm demo in 2007, and later, Nexans delivered cables used for Hywind Scotland, commissioned in 2017, according to Katteland.

Katteland fully expects Nexans’ involvement in wind projects across the globe to grow, which stands as a testament to its rich, diverse history.

“We are pioneers; we are united; we are dedicated,” she said. “These are our company values, and these are the ones driving us.”

Nexans is ideally positioned to continue offering quality cable and cable systems as it moves into the next phase of global wind-energy development.

“Electrification is a key enabler for the green transition in the world, and with this, an increasing demand for cables,” Katteland said. “The wind industry worldwide is expected to grow with an additional 200 GW next decade, with a split of about 90 GW in Europe, 90 GW in Asia, and the remaining in the U.S.”

The future of U.S. offshore

Most of the offshore wind farms the next decade will be of the fixed bottom variety, but Katteland expects floating wind-farm technology to become more of a reality as well.

“As floating gets more mature, you will see floating wind farms being planned where bottom fixed cannot be built due to water depth,” she said. “There are several prospects in the early engineering stages, like outside California.”

Nexans is adding capacity to its plant in Halden, as well as reinforcing and adding capacity to its Charleston facility, which should support both the U.S. and European market, according to Katteland. Nexans is also investing in a state-of-the-art cable laying vessel, Nexans Aurora, a new cable-laying vessel built for the installation of interconnectors and export cables used in offshore wind.