Brüel & Kjær Vibro, one of the leading worldwide independent suppliers of condition monitoring solutions for rotating machinery, has launched its next-generation VCM-3 condition monitoring platform for a wide range of industries.

The VCM-3 is designed to increase the uptime and reduce overall life-cycle costs of pumps, fans, motors, gearboxes and many other types of machines, while increasing reliability.

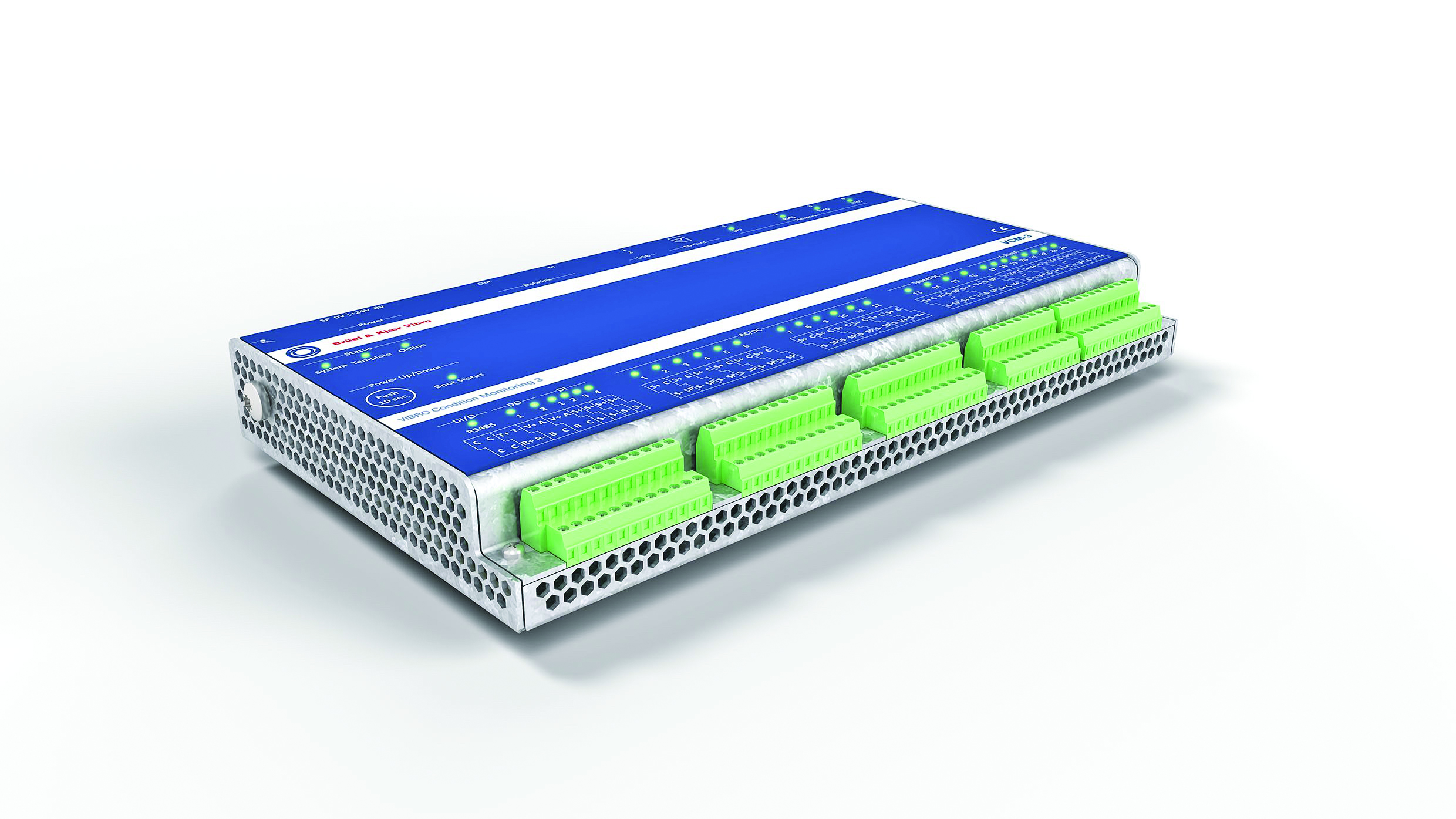

The field-proven VCM-3 is a 12-channel data acquisition hub targeted at full featured monitoring of auxiliary machines, balance-of-plant (BOP) non-critical machines and other assets in industries where cost-effective condition monitoring is required without machine protection. It features enhanced condition monitoring measurement techniques, easy system integration, built-in cyber security, and simple IT solution installation.

“The VCM-3 is designed to end any frustration monitoring your BOP and smaller, less critical machines,” said Albert Vontz, head of business unit industrial at Brüel & Kjær Vibro. “It is a more reliable and secure alternative to difficult walk-around monitoring rounds, and cost-effectively fills the gap between portables and rack-based systems. The VCM-3 has a powerful data acquisition and processing unit that provides a scalable platform for expansion, customization and development of future new monitoring methods.”

Users with all levels of in-house monitoring expertise can operate the platform’s diagnostic tools.

Key benefits of the platform include:

- Simultaneous input channels with high sampling frequency.

- Very easy to install.

- Robust cyber security.

- Internal (device) OPC UA server and storage.

- A worldwide network of sales and service offices and partners supports the VCM-3.

More info www.bkvibro.com