Since the beginning of the use of lubricants 5,500 years ago, there have been constant efforts to find ways to keep the lubricant clean and last longer. Early lubricants required frequent replacement. How did we know it needed replacing? Wheels started falling off carts at regular intervals. Folks knew that they needed to re-lubricate before that happened. They also noted that lubricant changes were required sooner when environmental conditions were less than ideal, such as a dust storm in the desert.

Frequently checking axles and yolks could ensure they could be reliable on a long trip. It could mean the difference between life and death.

Today’s modern power generation plant has lubrication issues that affect reliability just like in the old days. Some of these issues can still be life or death, yours or the equipment’s. It is still of paramount importance that conditions be checked on a regular basis. The more often you check, the sooner you find and correct a problem or stop a potential problem. This improves reliability and sustains the productivity of the plant.

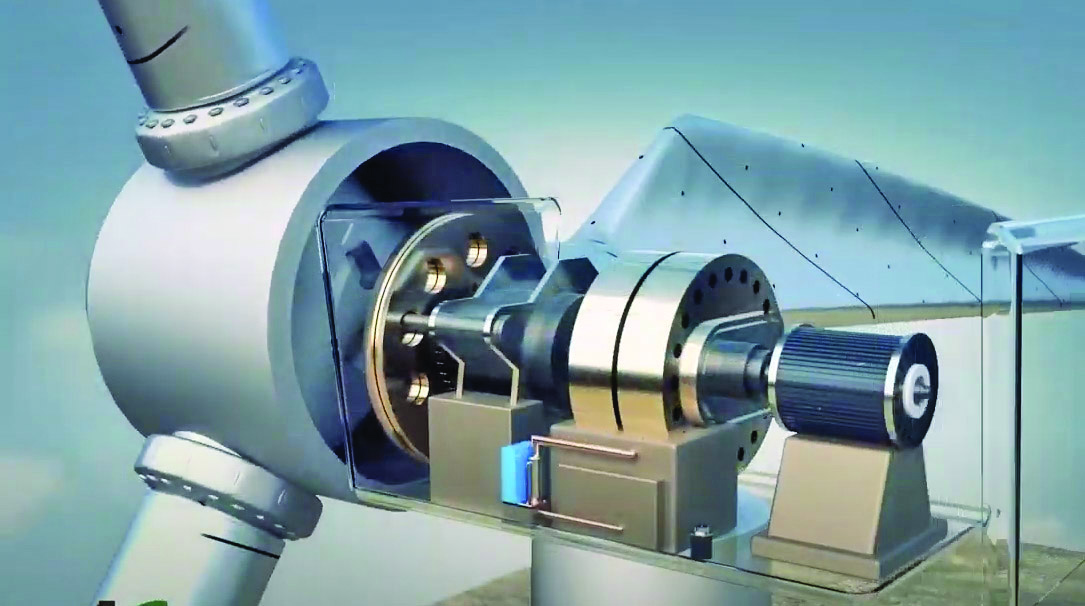

technology long used in power plants, is now available in wind turbines. (Courtesy: Shutterstock)

Improving Operation

Changing out the lubricant because of issues of contamination, useful life, or adverse environmental conditions are a few ways to improve reliable operation. Preventing lubricant degradation is another. New technology in additives and improved performance of Base 4 and 5 oil stocks can drive lubricant life. Other mechanical ways to prevent lubricant degradation include:

Water and moisture contamination can be eliminated with desiccant breathers and vacuum distillation.

Dust and dirt (larger micron-size particles) removal can use membrane filtration, kidney loop, ceramic filtration, and centrifugal filtration.

The elimination of sub-micron particles (fine, very small particles) requires advanced filtration methods such as charge agglomeration and electrostatic filtration.

Knowing that modern technicians have a variety of tools available to prevent and correct equipment problems due to contamination, how do they know the best tool to use for the job?

Multi-tools have become a regular item in a mechanics toolbelt. The best solution is a device that addresses all the issues associated with lubricant breakdown and failure. Until recently, there has not been a good single tool for wind turbines that could tackle issues such as moisture [1], oxidation, particulate contamination, and varnish formation.

Current Trends

New technological developments in the field of electrostatic attraction, a technology long used in power plants, is now available in wind turbines. Research and development performed by the University of North Dakota (UND) has proven it can be done. After testing next-generation electrostatic for utility scale power generation plants, UND has been testing electrostatic methods for advanced lubrication filtration. Researchers have found they can reduce particulate contamination to original or better ISO codes from manufacturers. It can even be accomplished with older lubricants containing varnish precursors.

So, if the technology exists to prevent lubricant degradation, then checking the system regularly will ensure operations are where they are supposed to be.

Advanced Filtration Technology

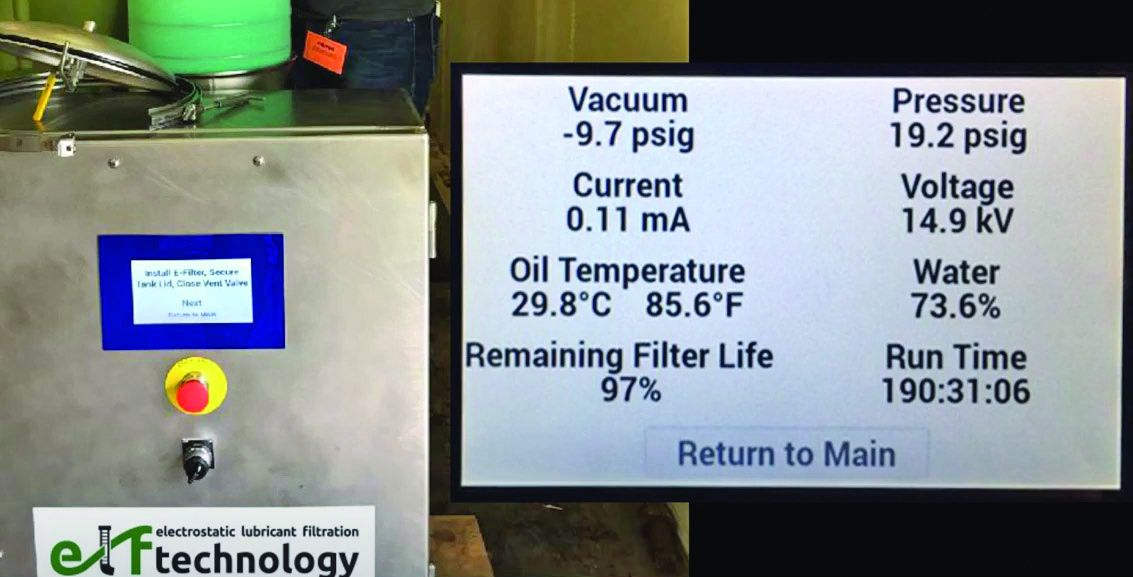

One such advanced filtration technology is Pangea’s ELF, an electrostatic filtration device with proven performance in power generating plants, and it is now ready for wind-turbine applications. With IoT technology attached, it can alert wind-turbine managers to trending conditions that may threaten their reliability program.

“Think of electrostatic lubricant filtration as a ‘dialysis for lubricants’; when ELF technology is combined with 24/7 IoT monitoring, it becomes a valuable solution for turbine manufacturers who seek to extend equipment life and reduce lubricant costs,” said Dan Bicz, president of Pangea Filtration Technology, a Florida-based company that deploys IoT cleantech such as ELF worldwide.

With the data from the university study, as well as power-plant operations to back it up, it is easy to see how advanced filtration technology can reduce the opportunity for lubricant degradation. What is most impressive is the addition of IoT technology to provide real-time management tools. This is a combination of technologies that has been needed for a while. Additional data can provide valuable information for wind-turbine operations where both environmental conditions and frequent inspections are both difficult to schedule.

Other Factors

Environmental considerations and performance expectations also have affected wind-turbine gearbox design. Smaller, more compact gearboxes under heavier loads are more demanding on lubricants. Other concerns such as extending lubricant change intervals and maintenance cost reductions put equipment at greater risk of wear and failure. Offshore wind farms have their own set of unique operational issues such as water contamination and temperature variations. [2]

With these ever-pressing demands on lubricants and the importance of the function they provide, it is clear newer technologies are needed to secure the continuous quality of lubricants. Keeping these systems moving provides national security and ensures a continuous supply of clean energy for homes and businesses.

References

Water contamination can be removed from Electrostatic filters when it is below 500 ppm.

Canter, N. (2019), “Challenges in implementing offshore wind power,” TLT, 75 (10), pp. 14-15.