In an era defined by the urgent need for sustainable resource management and the reduction of carbon emissions, wind power has emerged as a vital player in the global renewable energy landscape. As governments worldwide set increasingly ambitious climate goals, wind energy is positioned to play a pivotal role in transitioning away from fossil fuels. With a goal to triple global renewable energy capacity by 2030, as outlined in international climate discussions during COP28, the wind-energy sector is experiencing rapid growth. In the United States, this momentum is further supported by legislation like the Inflation Reduction Act (IRA), which offers substantial tax credits and financial incentives to foster investment in clean energy technologies.

Wind energy has proven to be one of the most effective solutions to meet the growing global energy demand. In 2023, wind power accounted for more than 8 percent of the world’s electricity, and this figure is projected to grow significantly in the coming years. According to the Global Wind Energy Council, global wind energy capacity is expected to increase by nearly 680 GW between 2023 and 2027. As the scale of wind projects increases, so do the number and scale of the logistical challenges linked to transporting the components required for setting up a wind farm.

What are the logistical challenges linked to transporting wind-power equipment?

- Size and weight of the equipment: Wind turbine components are massive. Nacelles—the housing for the turbine’s generator—can weigh up to 300 tons, while blades often exceed 100 feet in length. Transporting these oversized components requires highly specialized equipment and routes. A single wind turbine can require up to eight truckloads just to move from the manufacturing site to the installation location. This creates logistical bottlenecks, especially in areas with limited infrastructure or challenging terrain.

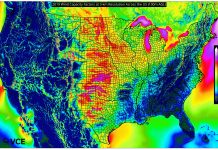

- Remote Locations: Choosing the location for a wind farm is a complex process that involves evaluating various factors. High wind speeds are essential, but other considerations, such as the terrain, topography, and environmental impact, are equally important. Since wind farms are often in remote areas with limited infrastructure, transportation routes need careful planning to allow bulky equipment to be transported smoothly. Additionally, the existing grid interconnection capabilities must be assessed and possibly upgraded to accommodate the wind-farm’s power output.

- Adverse Weather Conditions: Adverse weather events such as heavy rain, snow, or high winds can significantly complicate equipment transportation. These conditions make roads and access routes more challenging to navigate and increase the risk of accidents and damage to the equipment. High winds, in particular, can pose a danger when transporting large and sensitive components such as turbine blades, which require careful handling and balance.

- Delivery Delays: Coordinating the delivery of essential equipment is crucial in keeping wind-farm projects on schedule. The arrival of the significant components to the site must all be synchronized for a timely installation. Any delays can significantly affect project timelines and disrupt the overall construction flow.

- Transportation Damage: Given the scale and weight of wind-power components, transportation damage is a common challenge that must be addressed. Heavy equipment such as tower sections, which can weigh as much as 150,000 pounds, are particularly vulnerable to damage during transit. Damage can occur in several ways. Vibration and improper handling during transportation can cause components such as blades or nacelles to become misaligned. Bearings and other sensitive parts can be skewed, leading to mechanical issues that may not be immediately visible. Furthermore, cage damage, such as cracked or bent housing, can result in significant delays, as these parts often require special handling or repair before installation.

Cost Implications and Risks of Delays

Wind farms are expensive investments, with a single onshore wind turbine costing between $2 million and $4 million, depending on size and capacity [1]. The financial stakes are high, not only due to the cost of the turbines themselves but also because of the substantial risks associated with project delays. Any delay in delivery or installation can also have significant financial implications. Developers estimate that delays in wind-energy projects can lead to losses of up to $200,000 per MW. This means that for a 100 MW wind farm, a single day of delay could result in losses exceeding $20 million. Furthermore, the total sunk costs for canceled or delayed projects can reach $7.5 million, creating a financial burden that developers and operators must avoid [2].

What can be done to boost logistical efficiency?

There is no doubt that transporting wind-power equipment can be pretty challenging, and any setbacks can result in considerable financial losses. With the stakes this high, effective planning and continuous monitoring are not just beneficial — they’re essential for success. Many companies embrace the critical path method (CPM) to keep their projects on track and avoid costly delays. Coordinating the delivery of large equipment and all required components is no small feat and often requires a dedicated team of engineers and project coordinators. The complexities of the transportation and installation processes demand meticulous logistical planning and complete visibility throughout the transportation process.

Importance of Proper Planning

Transporting wind-power equipment requires meticulous planning at every stage to ensure success. Advanced planning tools allow companies to model the entire transportation process, covering everything from packaging optimization to task sequencing. Packaging optimization, for instance, is often overlooked but plays a vital role in protecting equipment from shocks, vibrations, moisture, and other environmental factors, ultimately minimizing damage and maximizing space within transport vehicles. Meanwhile, task sequencing facilitates a smoother installation process by ensuring equipment is packed and delivered in the correct order, aligning with the installation sequence. This careful coordination helps prevent bottlenecks during installation, contributing to timely and efficient project completion.

Adopting the ‘First-Time-Right’ Approach

The “First-Time-Right” approach focuses on using data and statistics to minimize errors in transportation and delivery. By ensuring everything is done correctly the first time, this method helps avoid delays and costly rework, leading to project success. By adopting advanced technology and real-time data, companies can better anticipate challenges and ensure smooth coordination and efficient delivery of the equipment to the installation site.

Leveraging Technology and Data for Precision and Efficiency

Digital modeling tools, real-time tracking systems, and predictive analytics help optimize wind-power logistics and ensure efficient transportation of turbine components from manufacturing to installation sites.

- Digital modeling and planning: Advanced planning software can simulate packaging configurations, optimize transport routes, and sequence tasks, which helps identify potential bottlenecks early on. This comprehensive modeling of the entire journey allows logistics teams to ensure all components are accounted for and risks are mitigated before issues arise.

- Data integration for coordination: By connecting data from various touchpoints, companies can create a more coordinated logistics process, significantly reducing the likelihood of miscommunication or errors that could lead to delays. Predictive analytics and historical data further enhance this approach, enabling companies to proactively anticipate logistical challenges and adjust their strategies. This ensures components arrive at installation sites exactly when needed and in optimal condition.

- Real-time monitoring technologies: Real-time tracking systems and IoT devices provide full visibility into the transportation process. These technologies enable logistics teams to monitor the movement and condition of the components continuously. They can quickly identify potential issues such as route disruptions, weather challenges, or equipment damage. Sensors can detect vibrations, impacts, or temperature changes during transport, and instant alerts allow for swift corrective actions, such as rerouting shipments or repairing components.

- Last mile delivery challenges: The last mile of wind-turbine delivery is often the most challenging due to the remote locations of many wind farms and rugged terrain. Installation Management uses real-time data and route optimization tools, equipping transportation teams with the necessary information to deliver massive turbine parts safely and on time. This strategy not only improves delivery accuracy but also reduces the high failure rates that often occur during initial installation attempts. Additionally, collaboration with local authorities and stakeholders can streamline logistics and facilitate smoother access to remote sites, enhancing overall operational efficiency.

Incorporating these advanced technologies ensures all components are accounted for and minimizes the risk of missing or incorrect parts. This aligns with the First-Time-Right methodology, which maintains the integrity of sensitive equipment throughout the logistics journey.

Sustainability and Financial Gains Through Data-Driven Efficiency

Beyond the financial benefits, optimizing wind-power logistics also contributes to environmental sustainability. Minimizing transportation damage and optimizing delivery schedules can reduce the carbon footprint associated with transporting wind-turbine components. In turn, fewer replacement parts, less rework, and more efficient delivery leads to lower emissions, aligning with global sustainability goals. In addition, switching to optimized packaging materials that are easily recyclable within local waste streams supports environmental goals. By integrating technology and data into logistics processes, the First-Time-Right approach maximizes efficiency and promotes eco-friendly practices, thereby aiding the global shift toward reduced carbon emissions.

The Path to Efficient Wind-Power Transportation

As the world moves toward ambitious renewable energy targets, the wind power sector must address its logistical challenges head-on. Transportation of wind-power equipment is a complex, resource-intensive process, but the proper planning and technology can overcome these challenges.

The First-Time-Right approach, supported by advanced planning, real-time monitoring, and efficient last-mile optimization, ensures wind-power projects are completed on time and within budget. By adopting this approach, wind-power developers can reduce costs, improve project timelines, and contribute to a cleaner, more sustainable future. In the race to meet global renewable energy goals, ensuring the efficient and timely transportation of wind-power equipment is not just a logistical challenge — it’s a necessity.

About the author

Hannu Hyttinen is the regional managing director for Nefab US West, leading end-to-end business operations and strategy across multiple locations in nine states. With more than 15 years of experience in Asia, including leadership roles in China and Vietnam for companies such as Nokia, Microsoft, and Nefab, Hyttinen brings a wealth of international expertise to his role. Since joining Nefab in 2016, he launched and led Nefab Vietnam as managing director until October 2023, when he transitioned to his current position in the United States.

References

- https://weatherguardwind.com/how-much-does-wind-turbine-cost-worth-it/#:~:text=%241%2C300%2C000%20USD%20per%20megawatt.,on%20wind%20turbine%20operational%20cost

- https://tamarindo.global/articles/half-of-us-wind-projects-face-major-delays/#:~:text=Respondents%20reported%20that%20developers%20lose,being%20aware%20of%20the%20risks