In the face of rising pressure to meet sustainability goals, manufacturers are urgently seeking the most energy efficient ways to produce parts for demanding applications without compromising on strength or performance. Exploring the pros and cons of CNC machining versus 3D printing can help manufacturers select the right technology.

NetZero Now or Never

The industrial sector is responsible for 24 percent of emissions in the U.S., according to the US Environmental Protection Agency (EPA), a figure that doesn’t even factor in the huge environmental impact of shipping parts across the globe. In the renewables sector, the race to NetZero combined with increasing demand for wind energy is placing growing pressure on companies to seek out more efficient processes and materials for manufacturing wind-turbine parts and components.

Harnessing renewable energy itself doesn’t come without its own challenges, but there is also the manufacturing of renewable energy components, which often requires complex processes and high precision. Added to this are extreme environmental conditions, rigorous industry regulations, keeping operational costs low, as well as powering society continuously — all elements that must be carefully considered when manufacturing parts for energy-industry applications.

The Game-Changing Benefits of 3D Printing

It is becoming clear that additive manufacturing (AM), or 3D printing, has merely scratched the surface of its potential and is poised to be a game changer for the future of the energy generation industry. It has the potential to bring a step-change in cost and performance competitiveness in the wind industry, while contributing to decarbonization efforts.

Major trends in supply chain and sustainability are driving demand for a global market estimated to reach more than $50 billion by 2025, as a growing number of manufacturers are embracing the benefits of this rapidly emerging technology.

Its rise presents a compelling proposition to the energy sector, ensuring fast turnaround times and enabling customization through design flexibility while improving energy efficiency and eliminating expensive tooling costs. Moreover, it allows for cost-effective rapid prototyping, speeding up the development of new energy technologies. As a result, manufacturers are employing online 3D printing to accelerate the deployment of new renewable energy sources.

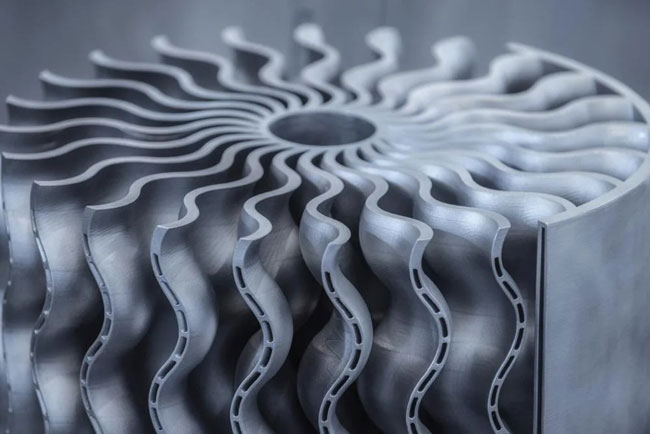

As AM or 3D printing does not require a tool or mold, producers may create more efficient, high-strength, lightweight structures where traditional manufacturing procedures fail. This is especially essential considering that raw material costs are rising around the world, making material consumption reduction an increasingly vital factor in product development and manufacturing. For most components, excess material from conventional manufacturing may be removed during the design stage, making 3D printing more cost effective over the whole lifecycle of the part.

What is particularly alluring about 3D printing’s multiple benefits is its customization capabilities, something which is a strong selling point for the technology in the wind sector. It means more efficient designs can be customized to specific locations and applications; for instance, while the standard design for a wind turbine at a given location may call for towers to be 90 meters tall, more precise evaluations onsite may reveal that towers of 120 meters tall are a more logical solution in one specific section. What this also translates to is the possibility of 3D printing 30-meter tower components onsite to add to the existing, standard 90-meter base in order to achieve optimal performance. This strategy is more sustainable than traditional practices for two reasons: Firstly, it would increase the overall quantity of clean, renewable energy that may be generated, and, secondly, it would reduce the carbon footprint by lowering the number of components that need to be produced and transported for many miles.

Key IP Challenges

However, there are a few areas where the technology currently falls short: Increasing public focus on the energy industry, pandemic-related volatility, and recent events in Ukraine are all contributing to market disruption. During difficult times, businesses frequently turn to their intellectual property to safeguard their position in existing markets and create new opportunities. Because additive manufacturing is playing an increasingly essential role in facilitating these transformations, it is critical that IP strategies and portfolios be appropriate for the 3D-printing environment.

Perhaps the most serious intellectual property danger confronting the energy business as additive manufacturing grows is how to regulate the spread of digital files needed to additively manufacture products. To address this risk, organizations must establish patents and other intellectual property rights with an understanding of how to protect each phase in the additive manufacturing value chain.

AM Innovation: GE’s Haliade-X Offshore Turbine

One use case demonstrating the renewable energy transition with 3D printing is General Electric’s joint project to develop the world’s largest 3D printer for offshore wind applications. The technology is aimed to speed up and optimize the production of casting components of GE’s Haliade-X offshore turbine.

In 2021, the U.S. Department of Energy (DoE) granted GE a $6.7 million project to investigate the design and manufacturing of 3D printed wind-turbine blades. Working with Oak Ridge National Laboratory (ORNL) and the National Renewable Energy Laboratory (NREL), GE sought to boost the competitiveness of onshore and offshore wind energy by leveraging 3D printing to lower production costs and improve supply chain flexibility. The turbine blade tips that were fabricated using 3D printing and thermoplastic composites have various advantages, including being lighter than traditional counterparts. Lightweighting permits larger turbine rotors to create more power while also decreasing pressure on the turbine’s gearboxes, drivetrains, bearings, and foundation, as well as lowering turbine operators’ lifetime expenses.

Not only that, but when 3D-printed thermoplastic blade tips approach the end of their useful life, they may be melted down and recycled, which is an important feature of GE Renewable Energy’s initiative. The team is also looking into how other elements of the turbine blade might benefit from 3D printing technologies and thermoplastic materials to improve component time-to-market, quality, and sustainability. Through its adoption of 3D printing, GE is aiming to not only improve cost and performance competitiveness in the wind industry, but sees it accelerating the energy transition even more rapidly.

The Gains in CNC Machining

CNC machining plays a crucial role in overcoming the challenges found in manufacturing, allowing for high-precision manufacturing of components, which is key to improving the efficiency and functionality of wind-energy systems. Additionally, CNC machining offers other advantages by helping reduce costs and waste in the production process, making renewable energy solutions more affordable and accessible.

Wind-turbine blades, often comprised of composite materials, must be manufactured with great precision to ensure optimal performance. These blades can be precisely carved and shaped using CNC machining, allowing them to catch wind energy more efficiently and to withstand wind pressure without disintegration; specialist metals and carbon fiber are crucial for ensuring the blades remain lightweight. Furthermore, CNC machining can be used to manufacture other wind-turbine components such as gearbox housings and generator frames. In fact, the majority of the critical driving components and blades found inside the turbine’s nacelle housing are among the most common wind-turbine parts manufactured with CNC machining. Other driving components include gears, rotors, main shafts, braking components, hubs, and YAW system components.

Aside from generating driving components, CNC machining makes it easier to manufacture the massive pitch bearings necessary for the wind turbine’s blade angle adjustment mechanism.

Additionally, the use of CNC machining in wind-energy production can assist in waste reduction as more precise cutting means less material use. This not only assists in lowering costs but also helps to ensure the long-term viability of wind-energy generation.

Harsh environment applications call for robustness and durability, another reason why CNC machining is the manufacturing method of choice as it can produce long-lasting parts that are critical to endure enormous stress and the wear of consistent use while maintaining dimensional stability.

Design and Cost Challenges

While CNC machining provides greater dimensional accuracy than 3D printing, the quickly evolving innovation being seen in additive manufacturing means that perhaps it is only a matter of time before this changes and 3D printing technology matches, or even surpasses, CNC machining’s precision in this respect. And while CNC machining produces products with superior mechanical characteristics in all three dimensions, this makes the method frequently more expensive, particularly for smaller batches of items.

There are also a few other potential barriers to CNC machining adoption in the energy business. Certain design challenges related with CNC operations come into play; without additional tools, CNC machines struggle to produce parts with inner corners, hollow features, and undercuts. When making parts for the energy industry using these design elements, the machine would need to do additional setups, secondary operations, or tool changes, which would affect production costs and time.

The Future Landscape

Moving forward, the renewable energy sector is only going to increase and expand. As renewable energy manufacturers continue to look for ways to increase product capabilities and performance while simultaneously meeting ambitious goals for efficiency and sustainability, 3D printing offers an ideal solution. However, it is crucial not to overlook the benefits of CNC machining before making the right choice.