Monitoring wind-turbine drivetrains is one of the most cost-effective tools operators have, enabling them to transform the way wind assets are run and slash operations and maintenance costs. When combined with real-world engineering knowledge and powerful predictive analytics, drivetrain data — specifically vibration — provides months of lead time for major component faults, making catastrophic failures a thing of the past.

But many wind-farm owners and operators are sitting on a new opportunity. With their existing drivetrain monitoring systems, they can now access insights on the health of turbine foundations. As investors increasingly seek to extract additional value from their existing assets, life extension and repowering conversations are gathering pace, placing scrutiny on traditional inspection methods.

Armed with high-quality data on foundation health, operators can make the best decision for the long-term profitability of the asset, ensuring each turbine generates clean energy for as long as possible, at the lowest cost.

The status quo

Foundation health assessments are often conducted via periodic inspections and measurements on a particular subset of the foundations. This limitation is driven by cost and, in the case of destructive testing, reducing the damage to the foundation and any risk of accidentally damaging primary components in critical regions of the foundation. However, there are some fundamental shortcomings with this approach.

Civil structures, such as wind-turbine foundations, exhibit natural variation in their dynamic characteristics. This can be more significant than variation caused by damage and can depend on temperature, groundwater conditions, load level, and other uncontrollable factors. Foundations are often a softening system (e.g., non-linear soil behavior, crack opening, etc.) where damage may only be evident under higher load levels not observed in short monitoring campaigns. The result is an unknown bias — more likely biased low — from short-term monitoring.

A second challenge with monitoring a subset of foundations is that dangerous damage will go undetected until serious incidents, such as a collapse, occur. There is no record of all foundations in a wind farm failing near simultaneously. Failure first happens on the outlier(s). This could be a foundation where the concrete was poorly placed, or materials did not match their design characteristics. It could also be a foundation that experienced excessive loading. Intelligent approaches exist to predict these outliers, but there is always the possibility of error in sample selection when using a subset. Further, most existing techniques depend heavily on expert opinion and qualitative findings.

Thinking beyond a tiltmeter

With aging foundations, particularly in partial repowering scenarios, ongoing insight into foundation health is critical. In many situations, lenders or independent engineers will require regular foundation monitoring for life extension beyond the theoretical design life. Current theoretical calculations of design life are conservative, resulting in design lives that cannot support the desired operation timeframe of a project. This contradicts observation and detailed evaluation showing that many foundations perform acceptably far beyond the theoretical life.

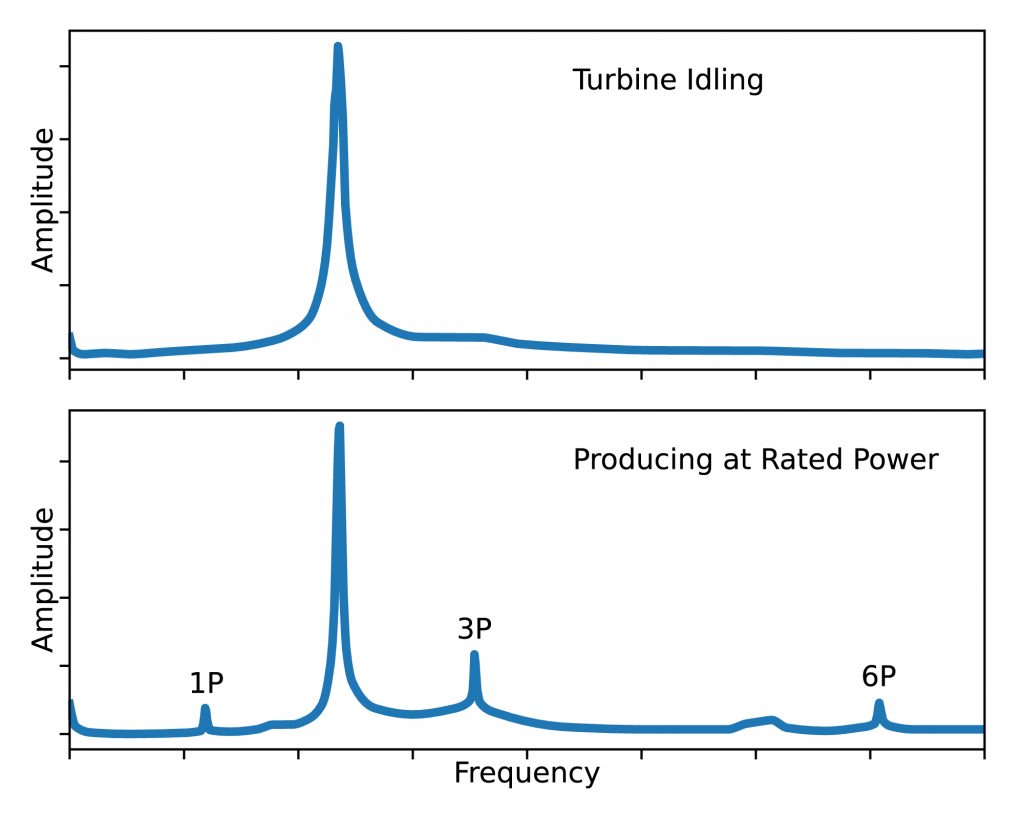

MEMS accelerometers, such as those used in ONYX Insight’s ecoCMS system, are extremely powerful for monitoring low frequencies, such as structural frequencies for wind turbines (Figure 1). Low-frequency capable CMS can deepen operators’ understanding of foundation health. These CMS are often already installed on projects, and if not, the installation costs will be less than the cost of periodic foundation testing and inspections for a subset of the project’s turbines.

Compared with the traditional approach, continuous observation of the entire population allows for:

- Statistical identification of outliers.

- Definition of alarm levels to initiate further action.

- Projections of when characteristics might exceed alarm levels.

- Early detection and clear decision criteria are vital when dealing with foundations.

Quantitative results allow operators to set decision criteria confidently, and projecting future conditions allows proactive action. Prediction of future statutes is essential to allow time for the design of possible foundation retrofits, construction contracting, and implementation, without significant project downtime or running turbines with the possibility of collapse.

Case study: Soil anchor degradation and repair

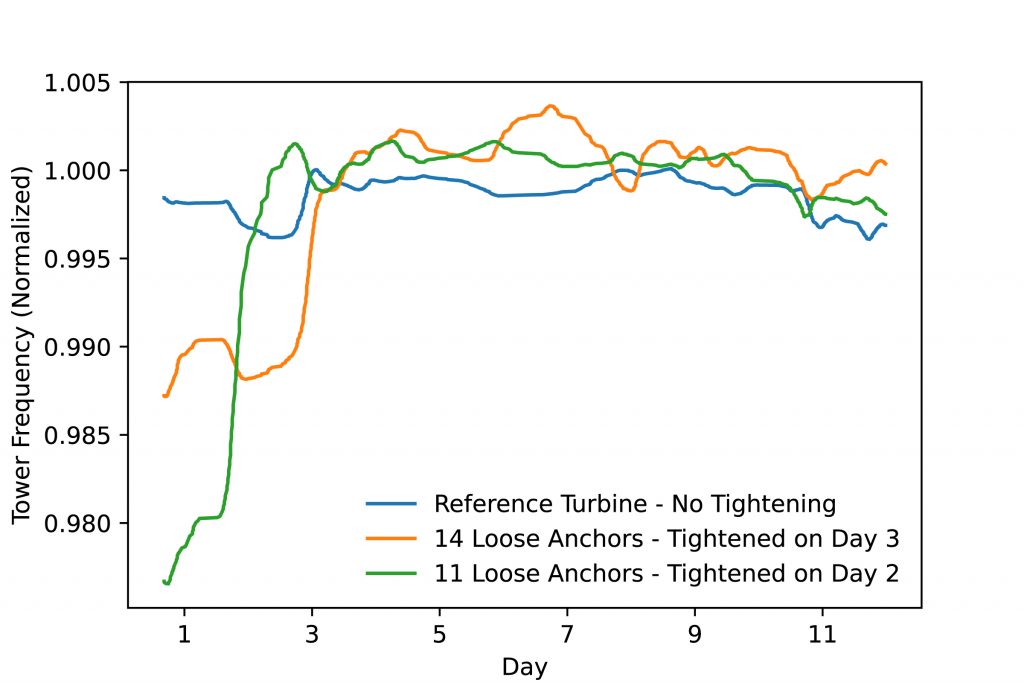

ONYX Insight’s ecoCMS is installed on more than 1,500 turbines belonging to a global supermajor. One of the wind farms experienced issues where the soil anchor bolts were loosening across the site. ONYX Insight was able to configure extended functionality for tower monitoring.

Over the course of the planned bolt tightening campaign, it was clearly demonstrated the system captured the change in foundation stiffness post-tightening — validating the effectiveness of the tightening program, and the analysis approach (See Figure 2). The site is now continuously monitored by ONYX for foundation health, providing peace of mind for the owner.

The need for tower and foundation monitoring is greater than ever Partial repowering and lifetime extension have enabled towers and foundations with a planned service-life sometimes exceeding 40 years — and replacing this infrastructure is not economically feasible. Another alternative — foundation strengthening — is exceptionally costly, and the designs are site-specific. In this area, continuous monitoring provides significant value to owners. Using reliable data, asset owners can defer strengthening work and implement targeted retrofits strategically where data shows statistically significant differences in foundation behavior.

Extending the functionality of a drivetrain CMS to infer tower and foundation health is not a substitute for other techniques. However, intelligent analysis, experienced experts, and proper due diligence can transform a drivetrain CMS into a triage tool to decide if, when, and where to deploy conventional techniques in a targeted, cost-effective manner. Fundamentally, this approach provides more certainty at a lower price point by enabling continuous complete project monitoring, capturing degradation that periodic snapshots will likely miss.