The scale of wind deployments is increasing rapidly, with offshore wind farms becoming larger and more remote, bringing both greater energy production potential and greater challenges for the industry’s suppliers and contractors. Amid these new challenges, the pressure on the wind industry to deliver on objectives, exacerbated by the expectations outlined at COP26, has already started to snowball. A team effort is needed to grow and sustain offshore wind production and maximize the provision of renewable energy.

In the context of providing both construction support, and operations and maintenance (O&M) services for these offshore wind farms, offshore energy support vessel (OESV) management is an area facing its own set of challenges — not only in developing vessels and crew with the versatility and expertise to transport technicians to site, but crucially in preserving the technical and operational availability of this fleet.

Ensuring the world’s emerging and operational offshore wind farms have vessels and crews that meet their stringent requirements is critical to upholding offshore wind’s position in the future energy mix. This means ensuring maximum availability of service, as well as compliance with health and safety, environmental requirements, and other industry regulations. OESV operators need an at-a-glance, comprehensive oversight of their operations so they can focus on the fast balls of changing market conditions.

Digitalization is gaining momentum in all industries, and the offshore wind industry needs to keep pace in embracing technology’s potential to simplify process management and support decision-making. The industry requires the safest, most reliable services to build and operate the wind assets that rank so highly on the environmental agenda. Those OESV fleet managers who embrace technical innovation in the form of integrated digital management systems (DMS) arm themselves and their customers with the ability to record and report data against these KPIs and grant themselves a competitive advantage over their peers.

What is a Digital Management System?

Digital management systems provide fleet managers with a means to manage large volumes of crew and vessel data to inform critical decision making. Digitized systems are not new to the OESV sector, but the systems available to fleet managers currently tend to work in isolation with individual data streams. This leaves fleet managers trying to glean insights from siloed datasets of varying quality, with opportunities for improvement slipping between the gaps.

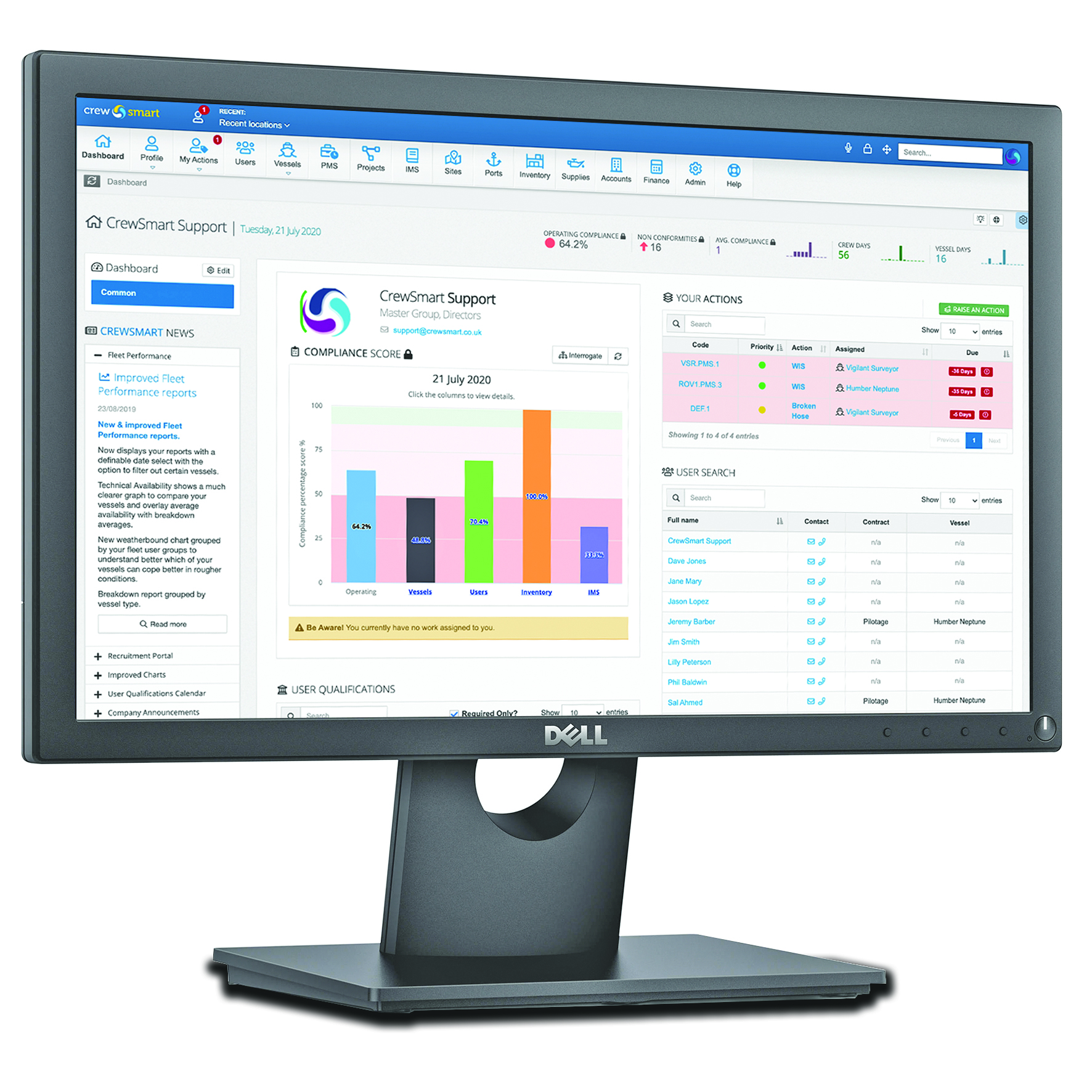

Integrated DMSs offer fleet managers a centralized view of all data streams within a single interface — a one-stop-shop solution that grants a complete overview of their vessel and crew, as well as the ability to plan maintenance timelines, manage and guide operational performance, check and manage fuel consumption, make proactive safety precautions and monitor incidents, optimize health and safety of their staff, and remain compliant. DMSs will also ensure an operator’s KPIs for their business and stakeholders are prioritized, supporting operational delivery to the highest standards and measuring success across various elements of vessel management.

Key advantages for OESV managers

With vessels providing the backbone for the support of long-term offshore wind projects and with these projects growing more complex to service, the need for data-enabled insights to drive strategic decisions is more pressing than ever. CrewSmart has built its expertise in delivering end-to-end crew and fleet management support service for all personnel, operational, commercial, and financial maritime management requirements.

Four key areas emerge in which CrewSmart demonstrates how integrated management systems can intelligently makes managers’ lives easier in the OESV space and offers tangible advantages for offshore wind construction, operation, and maintenance:

Compliance

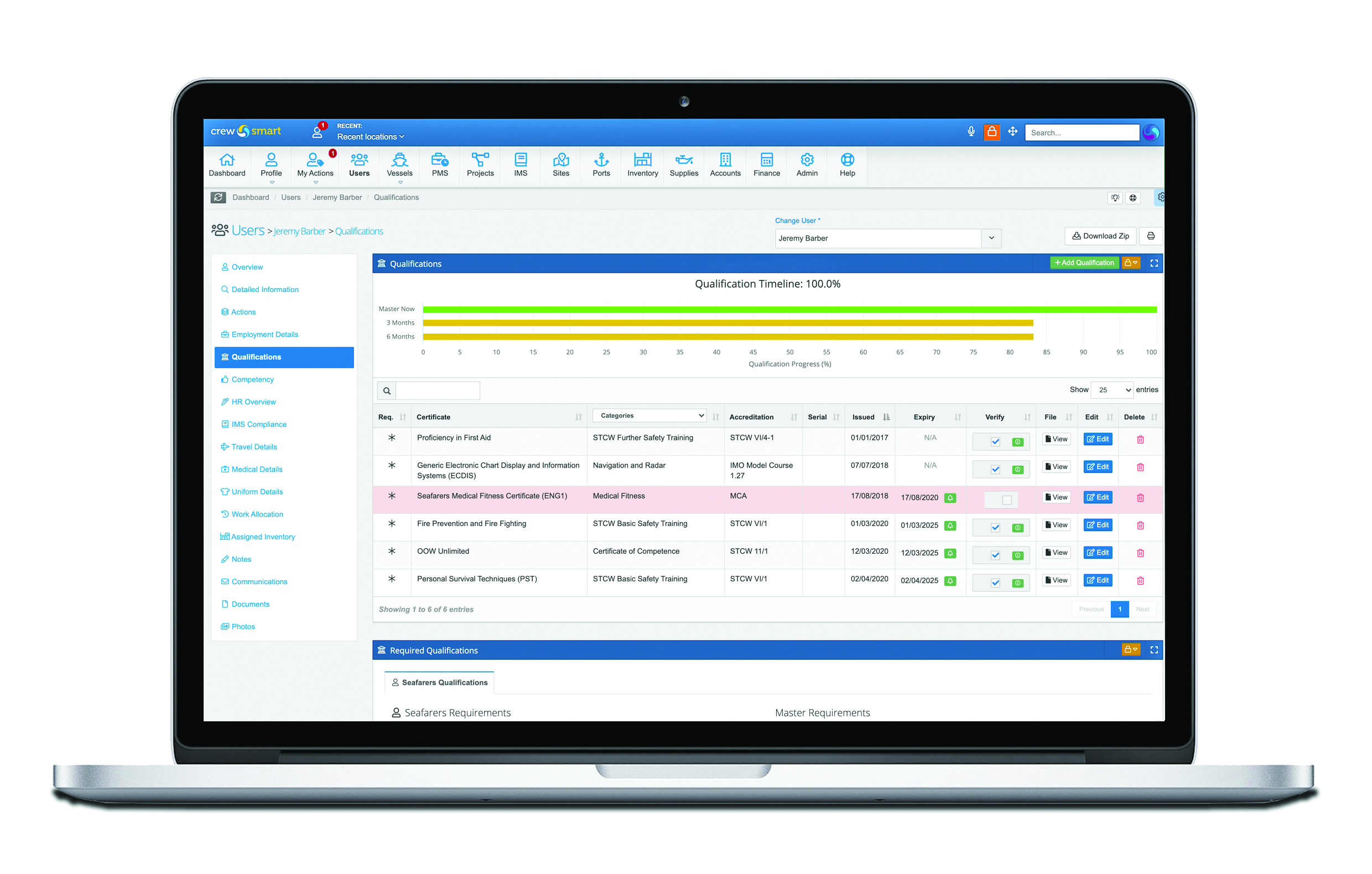

Compliance is essential for mitigating legal, reputational, and financial risks to your business, and with stricter regulation of the offshore wind sector and its supply chain in play, these risks are evolving in magnitude. A slip in compliance can take vessels and crews out of circulation in the best of scenarios or generate considerable risks to personnel and projects at worst. CrewSmart’s DMS grants complete compliance oversight of vessel and equipment certification, inventory, planned maintenance, and safety management. These compliance metrics scale across crew qualifications and training, too, as well as visas and work permits for effective crew management, while shared access from crews and shoreside staff shares the administrative burden and fosters a greater culture of compliance across the team.

Oversight

For effective decision-making, fleet managers need full visibility of critical operational activity on one platform. An effective digital management system should operate as a single point of access for all essential company data, and should encompass personnel, operational, commercial, and financial information, while empowering these teams and departments to take ownership of their responsibilities within the system.

Alongside compliance management of personnel documentation, crew managers using CrewSmart can manage and monitor personnel movements, assigning them to vessels and preparing travel logistics; meanwhile, commercial managers gain oversight over contract and documentation management. Financial managers can cross-reference information logged by personnel with deployed hours and client KPIs to simplify and evidence data for billing, and crew and technicians can use the same platform to access time-sensitive information for planning maintenance schedules to ensure maximum vessel availability for customers.

Efficiency

Efficiency is so often talked about, but so difficult to prove, that it fringes the territory of industry buzz words with almost no meaning. The effect of efficiency improvements for the end user depends on an understanding of what form that efficiency takes. In the case of CrewSmart, efficiency equals time and resources saved through simplified business workflows and the more effective deployment of resources against management priorities.

With an integrated DMS, fleet managers can cross-reference multiple data streams to highlight and address pinch points in resources — whether they be personnel, vessels, or equipment — before they generate an adverse effect for the customer. Equally, this information enables identification of the best opportunities for resource deployment for both the customer and the team.

Value for customers

Critical to the success of any business is the ability to evidence the value of the service it provides to its customers; this is especially true in the OESV sector where offshore wind customers, under pressure from investors and regulators, seek to understand their supply chains in far greater depth. Integrated DMSs make this a far simpler task than other alternatives and empower fleet managers to deliver and evidence the highest standards of service to customers against their core KPIs.

CrewSmart’s ability to minimize off-hire events such as unplanned breakdowns or regulatory breaches through continued tracking and monitoring and facilitate predictive maintenance to keep assets healthy and compliant for longer periods, enables the regular fulfilment of customer objectives and preserves positive, transparent relationships, which invariably generate both continued business and new sales.

Conclusion

As the offshore wind industry faces game-changing challenges within the transition to renewable energy, the construction, operation, and maintenance of offshore wind installations are of paramount importance in preserving the sector’s ability to step up to the plate and carry the world forward into a zero-carbon future. Regulations, compliance, and health and safety standards within the supply chain are considerations beyond the direct control of offshore wind players, yet they have the potential to stop projects in their tracks. These pioneering energy leaders need to rest assured that their supply partners are equipped to deal with these challenges.

CrewSmart specializes in the provision of digital management solutions for fleet managers and vessel operators, with a particular niche in the offshore wind support space. The stakes are high for its supply chain to meet growing demands and increasingly complex objectives — and it recognizes the importance of digitized processes in enabling the offshore support sector to drive its offshore wind partners through this journey. OESV operators share the responsibility of their customers in delivering a zero-emissions energy future. Integrated digital management systems, like CrewSmart, empower them to realize the full potential of this opportunity.