Sulzer Schmid, a Swiss company pioneering UAV technology for rotor blade inspections, and NNAISENSE, a world leading artificial intelligence specialist, have partnered to develop an artificial intelligence engine to automatically detect rotor-blade damages on wind turbines. This leapfrog technology is expected to bring the twin benefits of improving the productivity and consistency of blade-inspection processes.

With this new development effort, the two partners are aiming to build the industry’s most powerful artificial-intelligence engine able to recognize damages based on inspection-image material. The initial version will be able to flag all areas of concern on any given damaged blade. Ensuing upgrades will add other capabilities, such as the ability to establish damage categories and severity levels.

“Maintaining the structural integrity of rotor blades is critical to maximizing energy output and ensuring the safe operation of wind turbines,” said Faustino Gomez, CEO of NNAISENSE. “We are convinced that we will be able to transfer our extensive expertise in surface defect recognition from other industries to the wind industry and are looking forward to our cooperation with Sulzer Schmid, an innovator in its own space.”

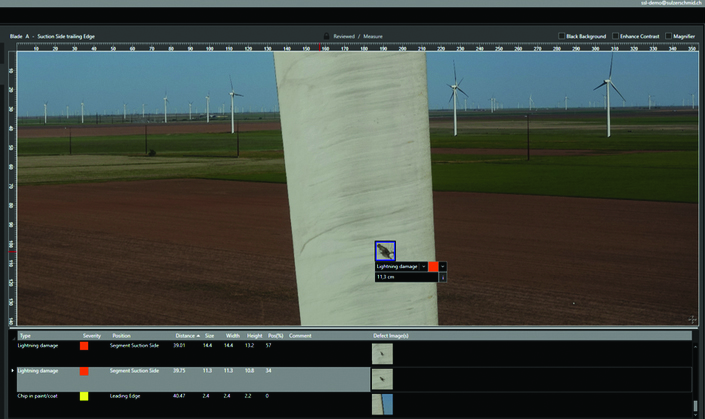

The autonomously flying drones of the 3DX™ Inspection Platform of Sulzer Schmid assure high-definition quality and consistent image acquisition time as well as 100-percent blade coverage while minimizing human errors and operational risks. The cutting-edge image assessment tools of the platform ensure detailed and efficient damage assessment. With the support of an AI-enabled inspection software, the review work of blade experts will be greatly facilitated. Instead of having to review the entire surface of the blades, they will simply need to focus on the pre-selected areas of concern. This technology progress will not only significantly boost the productivity of the reviewing teams but will also improve the quality of damage annotation processes.

“Maximizing end-to-end productivity is a key success factor in the highly competitive market of wind-turbine inspection solutions,” said Christof Schmid, COO and co-founder of Sulzer Schmid. “Thanks to our collaboration with NNAISENSE, we will be able to push the envelope in this area and significantly advance the automation capabilities of our inspection platform.”

“We are very excited about our collaboration with NNAISENSE, a true leader in the visual recognition of surface damages by means of AI,” said Tom Sulzer, CEO and co-founder of Sulzer Schmid. “This will further enhance the added value we provide for our customers and partners.”

More Info www.sulzer-schmid-labs.ch