Most wind turbines are built for a 20-year lifespan, but as many owners and operators have come to find out, problems with original mainshaft bearings can arise at any time — often within the first few years. The Timken Company, as a bearing and mechanical transmission solutions leader, has been active in the North American wind-energy industry for decades, helping customers avoid costly repairs by engineering stronger bearings for the toughest conditions.

To extend the life of mainshaft spherical roller bearings specifically, Timken developed ES302, a diamond-like coating (DLC) that adds durability where adhesive wear (the rubbing together of two metal surfaces) is a common problem. Timken scientists originally developed the special nanostructure coating for low-lubrication military applications but quickly saw the tremendous potential for ES302-coated bearings in other lubrication-starved, low-speed, high-load environments such as turbine mainshafts.

Previous lab results indicated that, compared to an uncoated bearing, an ES302-coated bearing could experience up to six times greater life when operated in standard conditions and up to three times greater life under debris-contaminated conditions. Field results would have to wait, however, as the first Timken wear-resistant spherical roller bearings (with the ES302 coating applied to the ends of the rollers) were delivered to customers starting in 2011.

Finally, more than seven years later, Timken scientists were presented an opportunity to reinforce initial lab results when one 230/600-series ES302-coated bearing was removed from its turbine (due to non-bearing-related issues) and returned for analysis at the request of Timken. A close examination showed the bearing was in excellent condition and would have easily reached 15 to 20 years of reliable operation had the turbine remained in service.

Given the enormous cost of replacing hard-to-reach mainshaft bearings, it is reasonable to assume that ES302-coated spherical roller bearings could save wind-farm operators hundreds of thousands of dollars over the lifespan of a single turbine by avoiding even one, if not multiple maintenance events. Looking deeper at the problem and what Timken discovered, turbine owners are encouraged to consider the operational advantages a stronger bearing solution can bring.

About Bearing Failure Rates

Table 1 summarizes the considerable amount of field data Timken has obtained for standard (non-coated) spherical roller bearings used in 3-point mount turbines operating in the U.S., with each plot representing the average failure rate for a given wind farm. The data suggests that mainshaft bearing failure is likely to occur inside of 10 years and remains a major issue for wind energy producers.

This has left many turbine owners to wonder why mainshaft bearing failures are so common. The simple answer, in the estimation of Timken experts, is that spherical roller bearings have long been the preferred bearing choice for mainshafts due to their dominance in the European market. As turbine models have migrated to North America, where different wind systems create different loading conditions, manufacturers have faced new scenarios requiring new design assumptions. And while the market continues to adapt to these challenges, there remains a significant number of standard spherical roller bearings in mainshaft applications. Seeing the potential for an upgraded solution to extend bearing life significantly, Timken engineered its ES302 coating to withstand the typical damage modes that cause mainshaft bearings to fail.

How Bearing Damage Occurs

In a standard mainshaft spherical roller bearing, radial and thrust forces result in higher loads on the downwind row of the bearing, as well as a full 360-degree loaded arc of rollers. For every shaft revolution, the full-loaded arc of rollers increases the number of stress cycles occurring on each point on the inner raceway of the bearing. Given that a mainshaft typically rotates at slow speeds in the 10-20 rpm range, this does not generate significant lubricant films, even with higher viscosity lubricants. The result is higher loads, more stress cycles, and thinner lubricant film thickness on the downwind row of the bearing, which increases the risk of micropitting, especially since sliding is present.

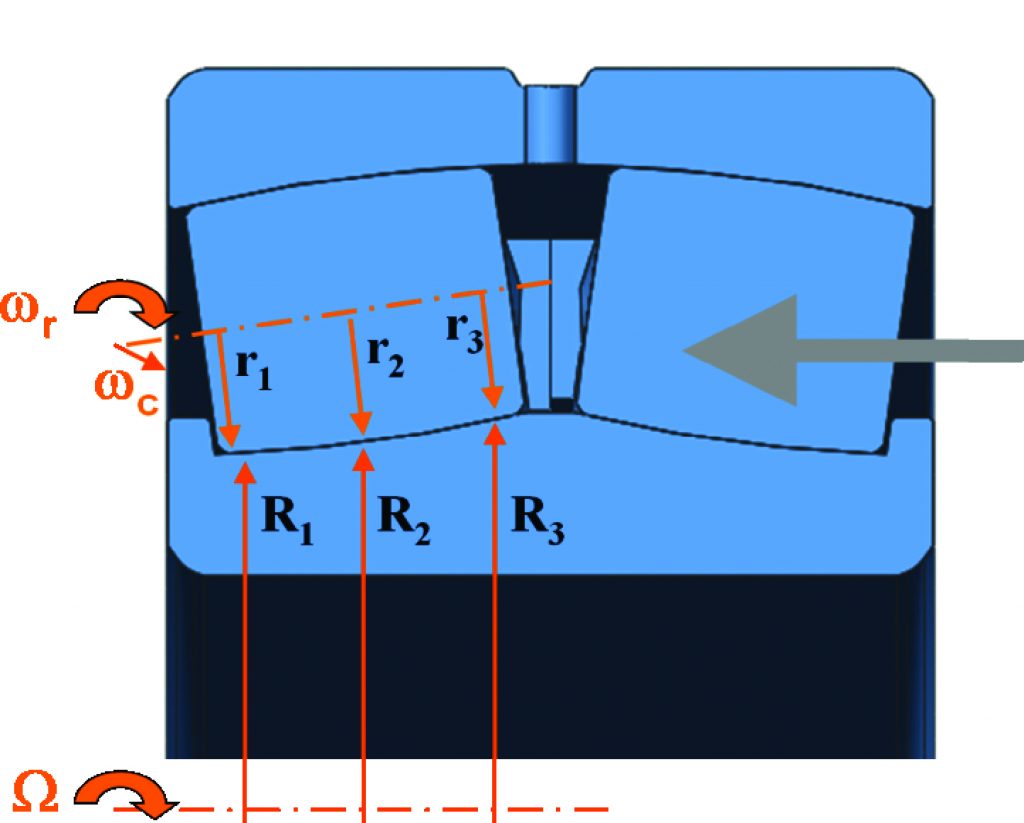

Rollers will slide on the downwind row raceway in mainshaft spherical roller bearings due to a phenomenon called Heathcoat slip. Heathcoat slip is a geometrical constraint suffered by spherical roller bearings. As illustrated in Figure 1, if surface velocities between the inner ring and the rollers match at locations 1 and 3, then the surface velocities must differ at location 2, which means that there is sliding between the roller and the center of the raceway. Specifically, the inner raceway will have a slower velocity, making the risk of micropitting extremely high for the downwind row.

All spherical roller bearings experience Heathcoat slip, but not all spherical roller bearings exhibit micro- pitting. For micropitting to occur, the lubricant film thickness must be insufficient to separate the residual finishing texture, or asperities, on the roller and raceway. That is, the lambda value (the ratio of the lubricant film thickness to the composite surface roughness) must be less than 1. Since the thickness of the lubricant film is a function of the entrainment velocity, low lambda conditions commonly occur at slow bearing rotation speeds. Therefore, the micropitting experienced by mainshaft spherical roller bearings is due to highly loaded roller/raceway sliding in low lambda conditions.

However, without highly trained tribologists (who tend to be more familiar with this type of wear) working alongside engineers in turbine design and maintenance facilities, the response by the industry oftentimes is to retrofit problematic mainshaft bearings with larger, higher fatigue load-rated bearings. For example, a common mainshaft spherical roller bearing for 1.5- to 2-MW wind turbines is the 230/600-series. In the field, it is common for these bearings to be replaced with 240/600-series bearings, which have longer rollers (spreading out the load on the raceway) and therefore have increased fatigue lives.

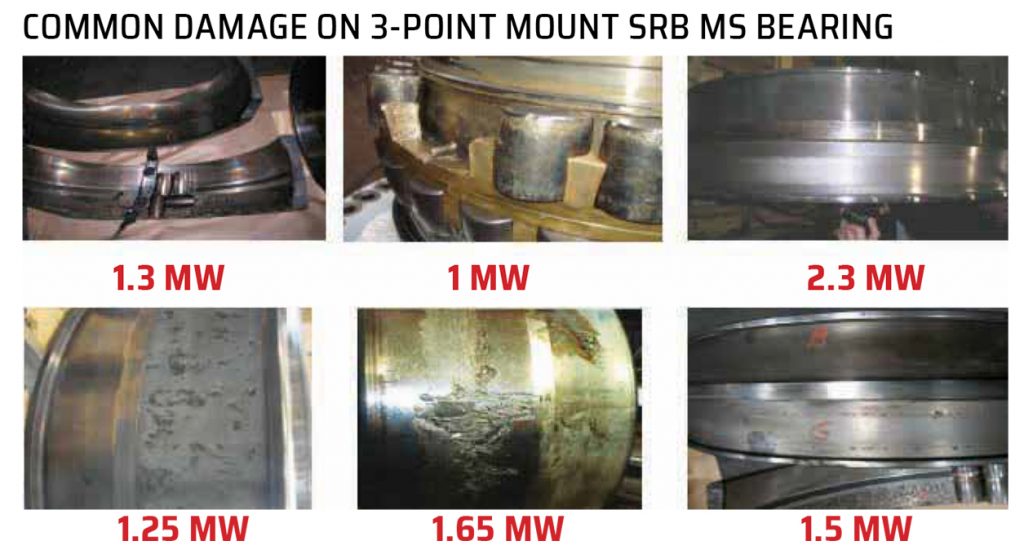

Naturally, the size of the bearing and the power of the turbine will also factor into the amount of bearing damage experienced. Despite this, Timken scientists have observed similar damage patterns in different turbine models over the years, given most mainshaft bearings experience high loading and repeated metal-to-metal contact. This adhesive wear can be seen in Table 2 in various non-coated spherical roller bearings (note the upwind side of the bearing will typically experience less damage).

A Stronger Coating Can Help

Since the late 1990s, Timken has employed surface-engineering technologies on bearing rollers to provide wear resistance and friction reduction to demanding customer applications. Decades of research and development have resulted in new technologies that, when used in combination, expand the performance of rolling element bearings well beyond previous limits.

In 2010, in response to the problems observed in standard mainshaft spherical roller bearings, Timken proposed applying a tungsten-containing-carbon-amorphous coating (ES302) to the spherical rollers of its engineered bearings. This DLC coating, effectively a crossover between a polymer and a ceramic, creates a material dissimilarity between the bearing rollers and raceway, which reduces the potential for the adhesive wear that Timken estimates to be the leading cause of mainshaft bearing failures in 3-point mount turbines.

The 230/600-series ES302-coated bearing that was returned to Timken in 2018 (the third of its kind ever produced) was originally manufactured in 2010 and installed on a 1.5-MW turbine in New Mexico in early 2011. In October of that year, the first uptower inspection was conducted, and like-new conditions were reported for the mainshaft bearing rollers and raceway. A second uptower inspection was conducted in May 2012, with only light debris damage noted. In November 2012, a third inspection confirmed the bearing remained in “good” condition. The bearing then operated continuously from 2013 to 2017 with no known issues before being removed from service last year.

Also notable is that in February 2012, a new gearbox was attached to the mainshaft and placed back into service (due to non-bearing-related issues), at which time Timken suspects some amount of contamination was introduced into the bearing cavity (likely sand and/or water). It was not until Timken was able to analyze the bearing in its labs that the contamination was discovered, though it does not appear to have negatively affected the performance of the bearing. (Due to the proprietary properties of the ES302 coating, the impact to the bearing was minimal.)

Inspection Shows Little-To-No Wear

After thorough analysis, Timken arrived at the following field performance results for its ES302-coated mainshaft spherical roller bearing that had seen seven years and three months service in New Mexico, with the bearing having been last relubricated in 2016. This series of inspections was performed to assess bearing condition after operation. Notably:

Grease sample analysis revealed moderate levels of iron content (attributed to normal raceway wear) and high concentrations of silicon (likely due to the potential contamination event in February 2012). As well, low concentrations of copper were detected, likely due to light wearing of the bearing’s brass cage. Based on particle concentrations, Timken observed only low-to-moderate wear and some evidence of external contamination during grease sample analysis.

Inspection of the bearing outer and inner ring revealed light-to-moderate fretting wear on the outer ring O.D. while the outer race was noted to be in “good” condition (as evidenced by visible grind lines, where a standard mainshaft spherical roller bearing would likely not exhibit grind lines at the same stage of operation). Minor debris denting and lubrication staining (the source of the discoloration in Figure 2) was also observed on the outer race. On the inner ring bore (the surface that contacts the mainshaft), some fretting wear was visible, while the inner raceway, noted to be in “good” condition, showed only minor discoloration and debris denting (possibly due to handling and removal).

Bearing roller inspection (Figure 3) showed that both roller complements were in “very good” condition, with the upwind roller complement exhibiting only minimal distress and light circumferential lining, while the downwind roller complement exhibited light circumferential lining and debris dents.

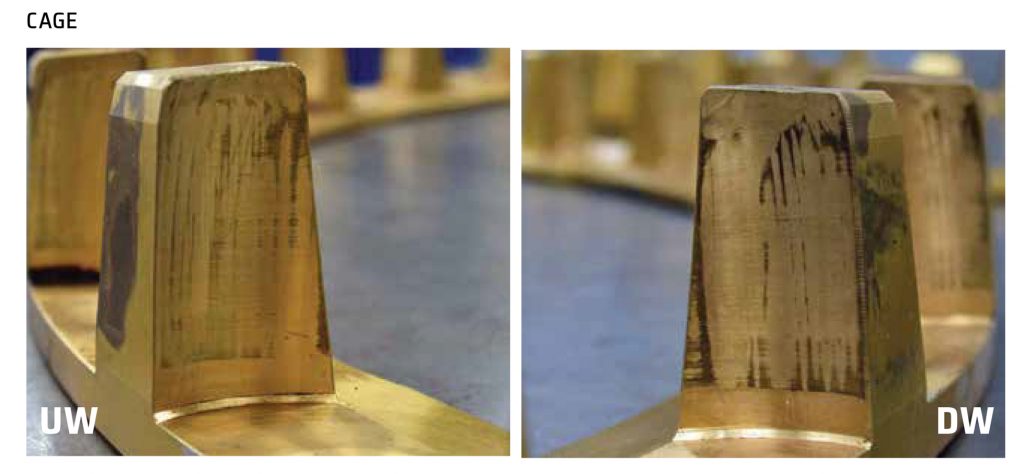

Brass cage inspection (Figure 4) revealed the cage bridges showed only minor discoloration in the pockets (most likely from the grease) and the complete cage was noted to be in “very good” condition.

Quantitative analysis of surface finishes, meanwhile, showed that outer ring, inner ring, and roller surface finish values were as expected post-operation, with the bearing raceways exhibiting little-to-no adhesive wear, and the upwind rollers showing “very smooth” surface finishes (downwind rollers showed slightly higher surface finishes, likely due to the influence of debris). Critically, all roller profiles were noted to be in “very good” condition, showing minimal signs of wear or deviation from their original profile.

Timken also conducted a hardness test to ensure that no significant damage was sustained by the bearing surfaces (that is, any major event that would have altered the surface structure of the bearing components, as observed under an electron microscope). This inspection verified that no extreme event occurred; however, analysis did reveal two white etch areas (or “butterflies”) originating from an inclusion or contaminant. In both cases, the white-etch areas were not the result of operating or application conditions and did not contribute to any pre-mature bearing damage.

Hardness testing further confirmed that all bearing surface and subsurface microstructures, which were thoroughly hardened, matched the expected outcome for the material and heat-treatment methods applied, indicating there was no significant change in bearing metallurgy during operation.

In summary

After seven-plus years of service, the Timken ES302-coated mainshaft spherical roller bearing installed in the 3-point turbine in New Mexico showed little-to-no adhesive wear, demonstrated the expected surface finish, and remained consistent with the original design profile, leading Timken to conclude the bearing was in “very good” condition for this stage of operation. Furthermore, there was no evidence of the bearing entering the next stages of damage. Based on its own application engineering practices, Timken can confidently estimate the bearing would have continued to provide reliable, trouble-free operation into the 15- to 20-year time frame had it not been taken out of service.

As U.S. turbine fleets continue to age, Timken will have access to more field data to compare the performance of different ES302-coated bearings. Presently, there are more than 1,000 such bearings helping to power a brighter future around the world, with a solid track record for performance and durability proven in the lab, and now in the field.

If bearing failures are a mounting concern for your wind farm, Timken experts, who have engineered stronger solutions for the world’s largest turbines for decades, can bring a unique insight and analysis to the problem. In addition to special coatings for mainshaft bearings, Timken has developed a full portfolio of wind bearing solutions and surface treatment options, all designed to help turbines go the distance without the downtime.

About the study

The Timken Company has sold bearings to the wind-energy industry for more than a decade, including ES302-coated mainshaft spherical roller bearings that first entered service in North America in 2011. While initial testing indicated the bearings would perform well under real-world conditions, field results have been difficult to obtain. Recently, a non-bearing-related changeout of a turbine drivetrain gave Timken scientists the opportunity to inspect one of these bearings and compare the results to the expectations for a bearing at this stage of service, more than seven years later. The ES302 coating, which received an Engineering Materials Achievement Award from ASM International in 2017, is a proprietary Timken technology not offered by any other competitor, and these are the first reported field results for the coating on a mainshaft spherical roller bearing application.