Wind turbines have been favored in many areas because of their ability to provide communities with environmentally friendly energy. According to Machinery Lubrication, most wind turbines are reliable 98 percent of the time. When they do fail, it is often due to failed or non-existent maintenance. Wind turbines can be expensive to operate, and any operational maintenance can prove costly to energy providers. Therefore, it is critical to identify potential failure points during manufacturing to prevent these issues from arising during operation.

Connectors

Several wind-turbine components should be lubricated to reduce downtime, including the circuit-breaker contacts, switch gears, slip-rings, and fusing systems that go into the turbine’s electrical distribution system. Electrical connectors are the physical interface between electrical equipment, wires, cables, and electrical circuits found in the power-distribution system. Without lubricant protection, contact metals are extremely susceptible to corrosion, resulting in a loss of connectivity over time, increased downtime, and added maintenance costs. Many factors contribute to contact corrosion in wind turbines, including micromovements, oxidation, mechanical wear, moisture, and aggressive chemicals.

Fretting corrosion is one of the major mechanical forms of deterioration of electrical terminals. Fretting corrosion is the result of micromovement between the mating surfaces of electrical terminals, which wears away the surface and allows an oxide layer to form on the contact. When an oxide layer forms on the contact, it creates an insulative layer between the contacts that causes an open circuit and increases contact resistance across the terminal. This causes the connector to act like a resistor that consumes power rather than passing it through the power lines. This micromotion can be caused by low amplitude vibrations or even by the thermal expansion and contraction of the contacts, meaning that nearly all contacts, even when stationary, are subject to fretting corrosion.

Often, lubricant experts will get the question, “But how do lubricants prevent connectivity issues when they interfere with conductivity?” This is a common myth associated with lubricants. When a lubricant is applied to a contact, it fills in the valleys of the contact surface to protect the metal from oxidation, and it is squeezed out of the asperities, allowing the current to flow.

Despite being housed within the nacelle, connectors are still affected by environmental conditions. Extreme temperatures, dirt, salt water, and moisture from humidity are a few factors that can affect connector performance within wind turbines.

Many engineers don’t consider lubricants during the design phase because they operate under a common misconception that grease attracts dirt, when in fact, it does the exact opposite. Grease creates an environmental barrier on the contact surface to seal the contact and keep out the dirt, dust, and moisture. This reduces the particulates that get in between the contacts that can create contact resistance.

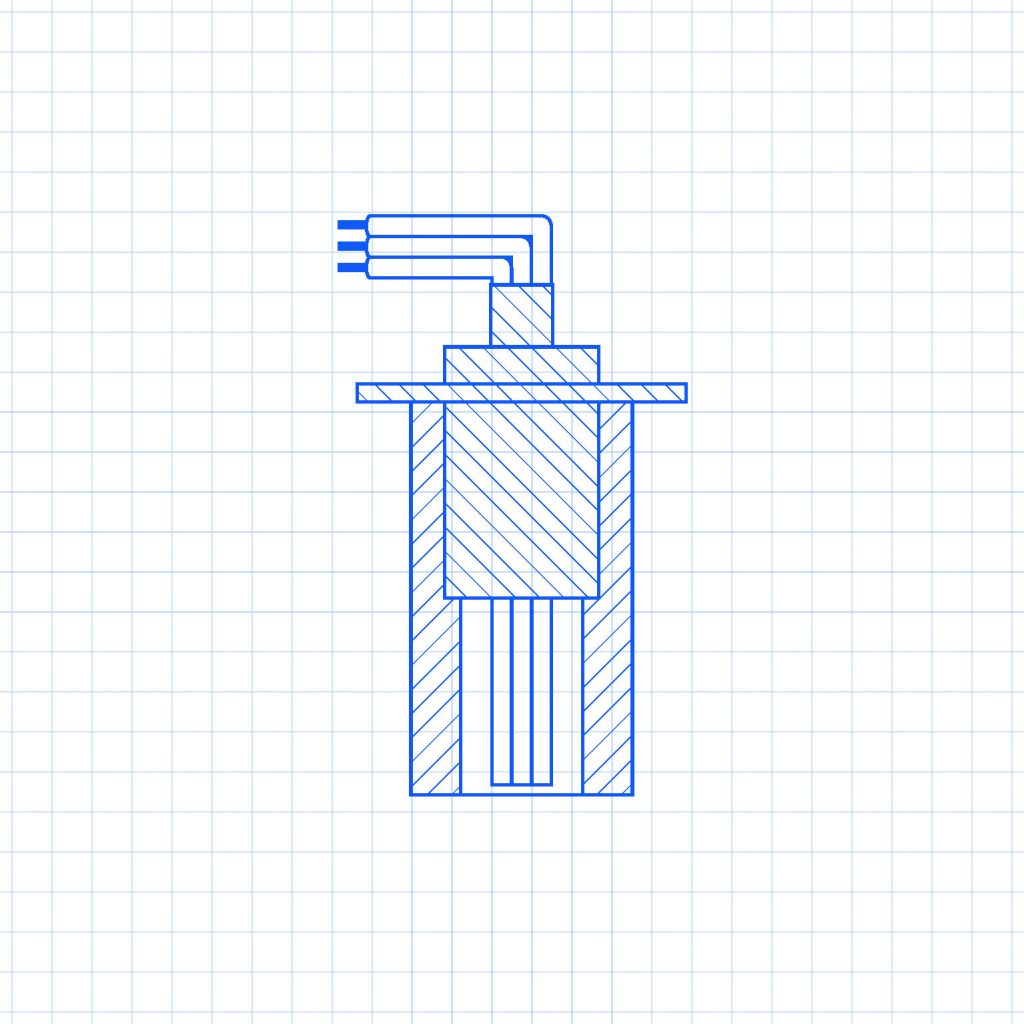

Slip-Rings

In a wind turbine, both signal and power electrical connections must be made between the rotating blade shaft and the stationary generator. This is accomplished by using a slip ring made of gold rings and gold fingers that ride along as the assembly rotates. These components should be lubricated to protect the interface of the sliding electrical contact surfaces to prevent oxidation and wear. However, if improperly selected, a grease can do more harm than good. Nye Lubricants was once approached by a customer after they noticed a buildup of black debris on their slip-rings. When paired with high vibration, this debris can corrode component surfaces and prevent conductivity. In this case, the OEM had been using an aerosol can to lubricate the slip rings. When lubricants are applied with an aerosol, molecules disperse in the air and can adhere to surrounding surfaces, causing contamination.

The most commonly recommended lubricant for these applications is a perfluoplyether oil, like Nye’s line of Uniflor™ lubricants. Compared to hydrocarbon lubricants, PFPE oils protect slip rings from debris and contamination while also creating a seal that reduces the wear on the gold rings and fingers of the slip ring.

Mechanical Drive Systems

Couplings play an important role in moving power from one shaft to another. High vibration in the nacelle makes it so that couplings are often misaligned.

While the couplings are designed to handle a degree of misalignment, designers must take extra steps to prevent additional wear between components. Lubricants designed for high-speed and high-torque applications create a stay-in-place lubricant barrier to protect the couplings from premature wear.

Lubrication Considerations

There are several factors that should be considered before choosing a lubricant for your wind turbine, such as the lubricants operational temperature range, life expectancy, and ability to withstand environmental conditions. Depending on the geographical location, a connector lubricant may need to perform in temperatures anywhere from -40 to 125°C without degrading.

Because the average nacelle is 250 feet above ground and the costs associated with downtime can be high, energy suppliers should select appropriate lubricants that last at least three to five years before re-lubrication. Material compatibility is another factor that should be considered. For example, certain lubricants attack plastics and are not recommended for use in connectors with plastic housings or elastomeric seals. The appropriate packaging must also be selected for the lubricant to improve and optimize dispensing.

In an ideal situation, a lubricant would be considered as a key design component to prevent downtime. If a lubricant is not considered in a wind turbine’s design phase, it is more likely to experience unexpected maintenance issues as the systems age and components wear. When a wind turbine does go down unexpectedly, having a reliable solution on hand is key to getting it up and running quickly, as well as preventing a reoccurrence.

Many prominent OEMs specify Nye Lubricant’s synthetic greases and oils into their wind-turbine designs and have seen increased performance and protection from wear, corrosion, and, ultimately, product failure.